Working principle of cooling tower

2022-03-16 10:49Working principle of cooling tower

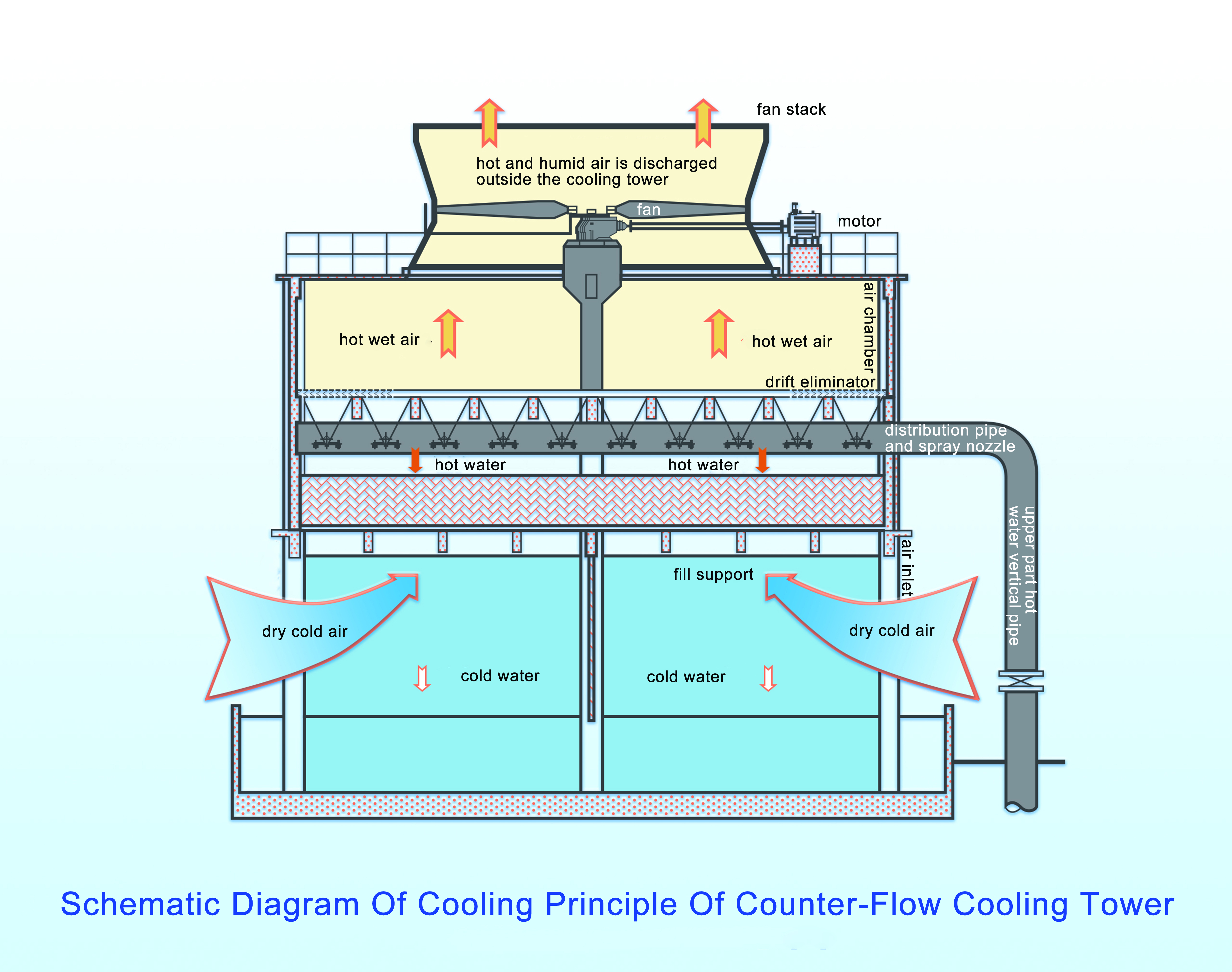

Cooling tower is a kind of equipment that uses the contact between water and air to dissipate the waste heat generated in industry or refrigeration and air conditioning through evaporation. The basic principle of its work is: the dry (low enthalpy) air enters the cooling tower from the air inlet network after being pumped by the fan; High temperature water molecules with high partial pressure of saturated steam flow to air with low pressure, and damp heat (high enthalpy) water is sprayed into the tower by the self seeding water system.

When water droplets come into contact with air, on the one hand, due to the direct heat transfer between air and, on the other hand, due to the pressure difference between the water vapor surface and air, evaporation occurs under the action of pressure. At present, it is to take away the latent heat of evaporation and take away the heat in the water, that is, evaporation heat transfer, so as to achieve the purpose of cooling.

Working process of cooling tower:

Take the working process of circular countercurrent cooling tower as an example: the hot water main machine room will circulate the water pressure to the water sowing system of the cooling tower through the pipe, transverse throat, curved throat and central throat through the water pump at a certain pressure, and evenly sprinkle the water on the filler through the small hole on the water sowing pipe; The dry low Han value air enters the tower from the bottom air inlet network under the action of the fan. When the hot water flows through the filler surface, a water film is formed to exchange heat with the air. The hot air with high humidity and high Han value is extracted from the top, and the cooling water drops into the bottom basin and flows into the main engine through the outlet pipe.

Generally, the air entering the tower is the air with dry and low wet bulb temperature. There is an obvious concentration difference and kinetic energy pressure difference between water and air. When the fan is running, under the action of static pressure in the tower, water molecules continue to evaporate into the air and become water vapor molecules, and the average kinetic energy of the remaining water molecules will be reduced, Thus, the temperature of circulating water decreases.

From the above analysis, it can be seen that the evaporation cooling has nothing to do with the air temperature (commonly known as the dry bulb temperature) being lower or higher than the water temperature. As long as the water molecules can continuously evaporate into the air, the water temperature will decrease. However, the evaporation of water into the air will not continue endlessly. When the air in contact with water is unsaturated, the water molecules evaporate into the air continuously, but when the air on the water air contact surface reaches saturation, the water molecules cannot evaporate, but are in a state of dynamic equilibrium. The number of water molecules evaporated is equal to the number of water molecules returned from the air to the water, and the water temperature remains unchanged. It can be seen that the drier the air in contact with water, the easier evaporation will be and the easier the water temperature will be reduced.

Application scope of cooling tower

The waste heat generated in the process of industrial production or refrigeration process is generally guided by cooling water. The function of the cooling tower is to heat exchange the cooling water with waste heat with the air in the tower, so that the waste heat is transmitted to the air and dispersed into the atmosphere. For example, in the thermal power plant, the boiler heats the water into high-temperature and high-pressure steam, pushes the steam turbine to do work, and makes the generator generate electricity. The waste steam after the steam turbine does work is discharged into the condenser for heat exchange with the cooling water, condensed into water, and then pumped back to the boiler for recycling. In this process, the waste heat of exhaust steam is transferred to the cooling water to raise the water temperature. The cooling water with waste heat transfers the heat to the air in the cooling tower and is discharged into the atmospheric environment from the air duct. Application scope of cooling tower: it is mainly used in air conditioning cooling system, refrigeration series, injection molding, tanning, foaming, power generation, steam turbine, aluminum profile processing, air compressor, industrial water cooling and other fields. The most widely used are air conditioning cooling, refrigeration and plastic chemical industries.