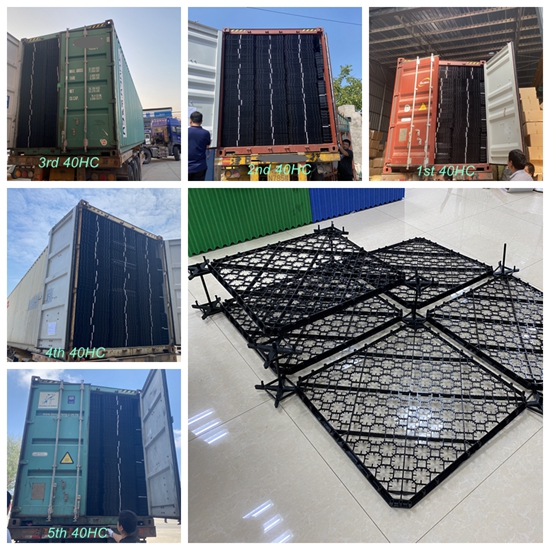

First Shipment for 5*40HC For Cooling Tower Golden Grid Fill

First Shipment for 5*40HC For Cooling Tower Golden Grid Fill

Cooling tower golden grid fill is widely used for the dirty cooling waters in the cooling tower, its cooling efficiency is superior.

Cooling Tower Grid Fills work on the principle of causing the flowing water to fall through a grid of splash bars/grids' causing the water droplets to break up and increasing the contact time between water and air. As the falling water encounters multiple layers of these grid fills, the droplets keep dividing into smaller sizes thereby increasing the heat transfer and thus cool the water.

Cooling Tower Film types fills have been popular with the Cooling Tower Industry as a result of their efficiency of not only handling large quantities of water but also the overall tower efficiency. However in the case of heavily contaminated water, film type fills are susceptible to accumulating deposits and often make way for the use of splash type fills for effective water cooling. The forgiving nature of splash fills towards 'dirty' water and imperfect water distribution is offset by the need to have larger towers and thus higher capital costs as well as pumping heads.

Latino just finshed the loading for first 5*40 HC for our regular customer Southeast Asia, for this cooling tower maintenance, it include the cooling tower golden grid fill, cooling tower nozzle, cooling tower drift eliminator, and FRP profiles which used to install as the cooling tower drift eliminator supports.

Once Latino received this cooling tower maintenance project, we supplied the preliminary bom based on the cutomer's supplied data for apprival, and we also supply the estiminated cooling effect by our engineer. Since the improper use of the cooling tower golden grid fill and the bracket, so it caused the collapse of whole grid fill. After confirming our golden grid fill could meet with their request cooling effect and our cooling tower parts quality, then our customer released this project to Latino, according to mutual communication, we finalize the final bom and supply the detailed installing pictures for final confirmation. For this cooling tower maintenance project, it coud been loaded into 10*40HC. Based on the request from the working site, Latino put this order into urgently production, we finished the production for the first 5*40HC within 15days, and in order to save the shipping cost for the customer, we packed 5 pieces in one bundle, and loaded this 5 containers within one and a half day. Here please find the stock picture as follows.

If you have any requests about the cooling tower maintenace project, please kindly contact us, Latino's engineer will supply our professional suggestion to you.