Inclined Tube Media Filler for Lamella Settler Water Distillers

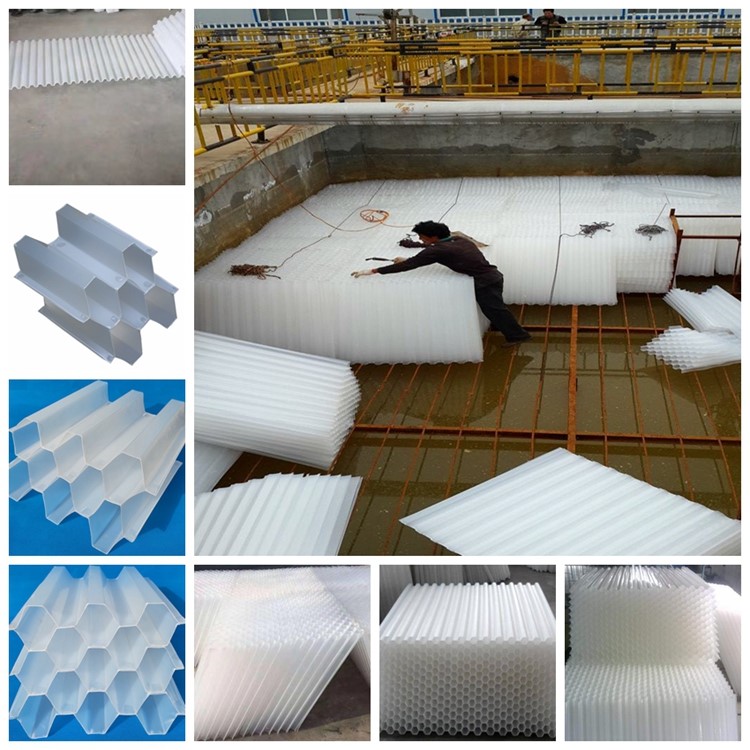

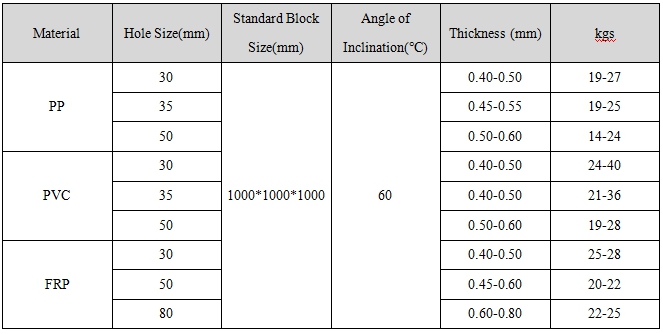

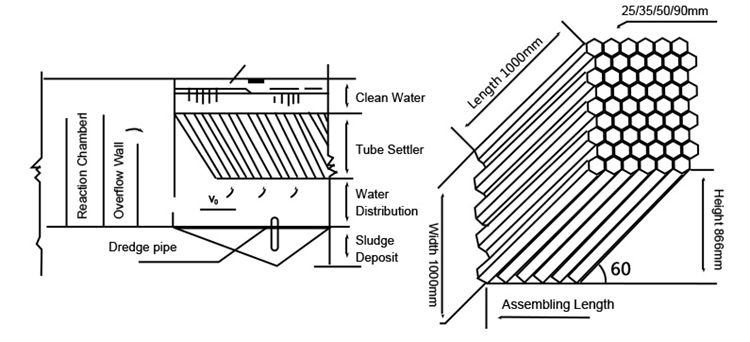

Inclined tube media filler is mainly made of ethylene propylene copolymer and polypropylene material. On the basis of the shallow theory, a sedimentation section with reasonable sedimentation distance is set up in the upper part of the inclined plate and the geometric shape of the sloping plate is controlled in the lower part to form a stable contact flocculation section in the lower part of the slanting plate. By contact action and shallow pool precipitation mechanism, Flower and water separation purposes. All kinds of spacing ramp packing are through different height of the plastic ribs to support the inclined plate, ribs and inclined plate hot-melt welding, between each two layers of inclined plate between the need for more ribs support, assembly process is complex, and the traditional ramp The internal flow path is rectangular and is only suitable for use in an upflow sedimentation tank.

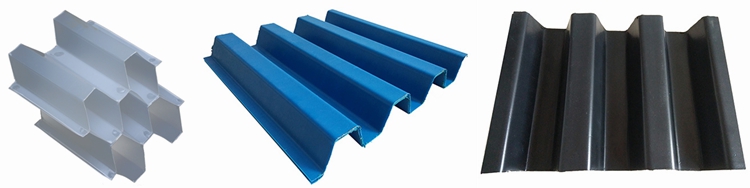

Inclined plate can be designed to support a variety of sizes, according to the parameters of the ramp to support the different requirements can be different angle of the ramp, angle and so on. Multi-functional and efficient combination ramp plate packing internal water flow channel is smooth, easy to mud mud, on the flow sedimentation tank and lateral flow sedimentation tank can be applied, so for a variety of water treatment process, its high strength, corrosion resistance, Detachable features make it significantly longer than the traditional ramp life. Multi-functional combination of ramp packing Before the assembly of slant plate in a number of holes, then the ramp support rod through the hole and the other connecting rod wedge force wedge, so that the two support rods and The slant plate can be fastened into a whole. Repeat this step to connect several slanting slabs into one whole. The whole installation process does not need any mechanical processing equipment, and the installation is extremely simple.