Latino's Maintenance Service For Air Cooling System

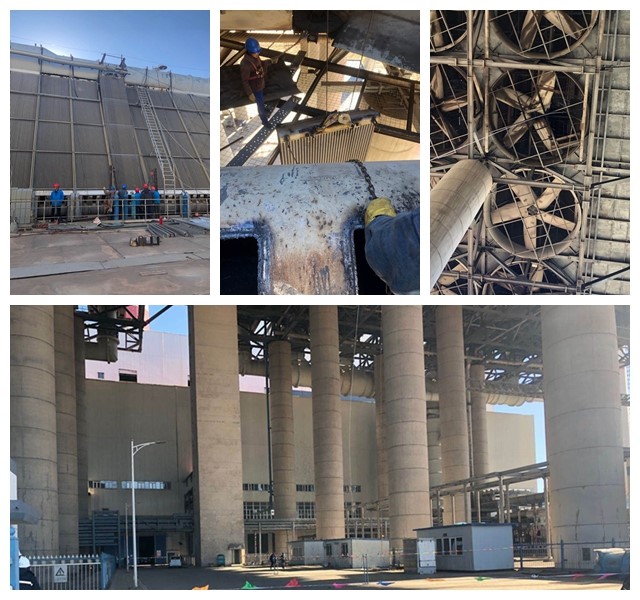

Recently, Latino are researching the maintenance service and ACC bundle for the air cooling system. Latino just cooperate with an electrical plant for the maintenance service, including the ACC bundle removing, ACC bundle production and installation.

Now Latino's whole team are removing the ACC bundles.

Later, we will update the installation process in our website.

An air cooled condenser (ACC) is a direct dry cooling system where steam is condensed inside air-cooled finned tubes. The cool ambient air flow outside the finned tubes is what removes heat and defines the functionality of an ACC. In thermal power plants (T), the steam from the turbine exhaust flows into the ACC where condensation occurs. Then the condensate returns to the boiler (B) in a closed loop. Since the steam coming from the turbine is at a low pressure, the ACC works at a pressure close to a vacuum, and non-condensable gases (G) are removed continuously by an air evacuation unit.

Air cooled condensers work well for power plants in water-scarce areas

Air cooled condensers are used for thermal power plants like combined cycle, concentrated solar, coal, biomass, and waste to energy. Since these kinds of power plants, which are equipped with ACCs, do not require a large volume of cooling water, the power plants can easily be built in a region where water may not be available, or where its use is restricted or expensive.

The building blocks of an air cooled condenser

An air cooled condenser is made up of modules that are arranged in parallel rows. Each module contains a number of fin tube bundles. An axial flow forces the cooling air across the heat exchange area of the fin tubes.

The typical set-up for an ACC installation includes:

the supporting structure

the steam ducting from the steam turbine interface

heat exchangers, finned tubes, fans, motors, gearboxes, and auxiliaries such as the condensate and drain pumps

condensate and duct drain tanks,

the air evacuation units

related piping works and instrumentation

Most air cooled condensers (ACC) have finned tubes very similar to the heat transfer surfaces in an HRSG. The fin region of the condenser tubes become fouled with environmental debris (road dust, pollution, bird nests, dead animals and material) that cause the unit to loose efficiency. These ACC systems can be quickly and easily cleaned by LATINO using our CO2 blasting technology. The CO2 process is dry and inert, does not cause corrosion and eliminates the waste and messy containment and clean-up required by water blasting these systems.

Fin Cleaning System For Air Cooled Condenser should be cleaned on regular basis to remove dirt, dust, greasy and oily soils, carbon deposits. Cleaning process is unavoidable and over a period of time will severely diminish production and profitability. Reduction of plant production can be by as much as 35% when compared to first commission values. So many corporations now recognize the real benefit of cleaning heat exchangers / air fin cleaning. In order to maintain their profitability and competitiveness in the current marketplace they are appointing specialist companies to clean the polluted heat exchanger fins, completely removing all the built up restricting material residue in the process. We started manufacturing cleaning equipment which requires just one person to operate and permenatly fixed on the tube bundles.