- Home

- >

News

Cooling tower nozzle is an important cooling tower components for the cooling tower. This cooling tower nozzle is widely used in crossflow and counterflow cooling tower. These cooling tower sprayer are installed by ABS pipe or FRP pipe in the middle of the tower and connected with the water distribution pipe. When the water flows by a certain press to the cooling tower nozzles, keeping the hot water rotating into the spray nozzles and then flow away from the spray nozzle bottom. Every cooling tower spray nozzle has the inlet and outlet. The inlet connected with water distribution pipe, and the outlet has special design in order to make the water spraying uniformly and continuous and the droplets drop down the cooling tower fills.

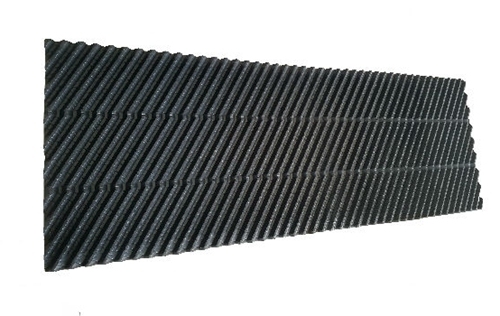

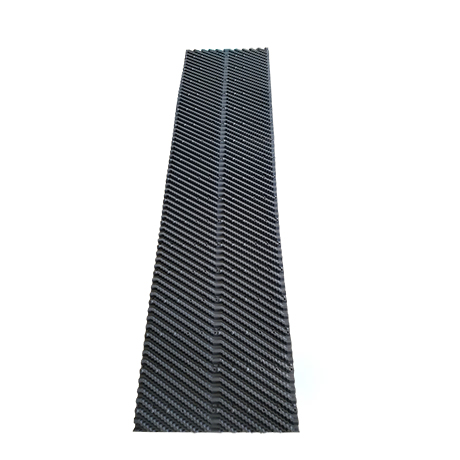

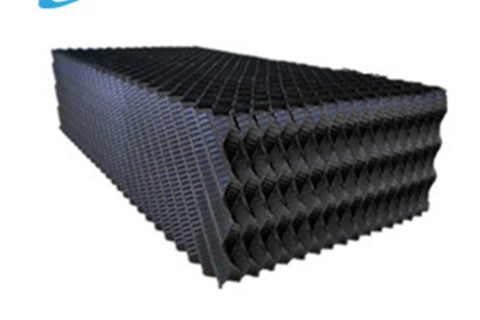

Cooling tower fill is one of the most important components for exchange of gas and water in cooling tower. The cooling tower fill is made by the cooling tower PVC sheet. The heat and resistance characteristic of the cooling tower fill are the main factors influencing the cooling efficiency. Moreover the quality of the material will influence the fill's lifetime. LATINO choose the high quality fill for the cooling tower. LATINO'S cooling tower fill is with the advantages of good chemical stability, resistant acid, alkali and organic solvent corrosion, high cooling efficiency, small ventilation resistance, strong hydrophilicity, large contact area etc.

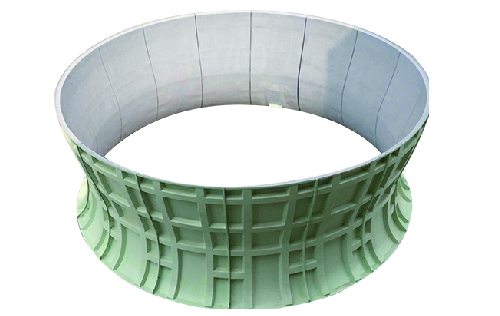

The fan stack is an essential part of the cooling tower as well as a part of the propeller fan, mitigating pressure loss produced by high input air speed.

Cooling tower fill is one of the most important components for exchange of gas and water in cooling tower. The cooling tower fill is made by the cooling tower PVC sheet. The heat and resistance characteristic of the cooling tower fill are the main factors influencing the cooling efficiency. Moreover the quality of the material will influence the fill's lifetime. LATINO choose the high quality fill for the cooling tower. LATINO'S cooling tower fill is with the advantages of good chemical stability, resistant acid, alkali and organic solvent corrosion, high cooling efficiency, small ventilation resistance, strong hydrophilicity, large contact area etc.

Cooling tower fill is one of the most important components for exchange of gas and water in cooling tower. The cooling tower fill is made by the cooling tower PVC sheet. The heat and resistance characteristic of the cooling tower fill are the main factors influencing the cooling efficiency. Moreover the quality of the material will influence the fill's lifetime. LATINO choose the high quality fill for the cooling tower. LATINO'S cooling tower fill is with the advantages of good chemical stability, resistant acid, alkali and organic solvent corrosion, high cooling efficiency, small ventilation resistance, strong hydrophilicity, large contact area etc.

Spiral Target Cross Flow Cooling Tower Spray Nozzle is made by PP material, and assembled by several parts. It is widely used for the counterflow cooling tower. Spiral Target Cross Flow Cooling Tower Spray Nozzle help ensure a uniformly delivery of water over the cooling tower fill. Uniform water distribution at the top of the cooling tower fill is essential to achieve proper wetting of the entire cooling tower infill surface.

The ABS spray nozzle is also called the hollow cone spray nozzle is available in two diameters and it's used on wood, steel, and fiberglass cooling towers, Natrual draft cooling tower and induced draft cooling tower. The cooling tower nozzle structure allows avoiding the formation of non-irrigated zones in the spray flame and achieving fine-dispersed sprinkling of water in the cooling tower, while the direct-flow shape of the cooling tower nozzle significantly reduces the likelihood of its being clogged with the admixtures in the water.

The ABS spray nozzle is also called the hollow cone spray nozzle is available in two diameters and it's used on wood, steel, and fiberglass cooling towers, Natrual draft cooling tower and induced draft cooling tower. The cooling tower nozzle structure allows avoiding the formation of non-irrigated zones in the spray flame and achieving fine-dispersed sprinkling of water in the cooling tower, while the direct-flow shape of the cooling tower nozzle significantly reduces the likelihood of its being clogged with the admixtures in the water.

Victory part--Overseas department of Latino company