Cooling Tower Grid Fill Installation From Latino

2021-03-11 11:08Cooling tower splash grid fill is the popular choice for use in all applications where water quality is very poor. This cooling tower infill is suitable for polluted cooling waters with high contents of suspended solids, oils and the like.

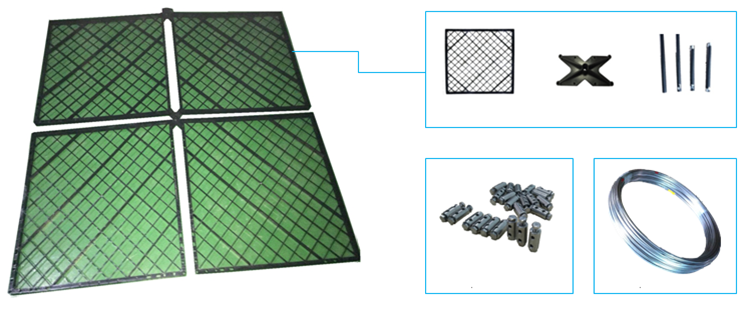

In accordance with the thermal design conditions several cooling tower fill layers are hanged from the structural beams by means of stainless steel wires, with each layer turned 90 degrees to the next lower level.

Latino just finished the installation for this cooling tower grid fill oversea. After the installation, the test cooling effiency is satisfy the enduser.

This cooling tower grid fill is a direct replacement splash fill for use in crossflow and counterflow towers where dirty water is a concern. Optimum performance in a splash fill is the result of maximizing the number of water droplets in order to produce the highest surface area of water available to the passing air. Narrow horizontal strips, in uniformly spaced tiers throughout the heat transfer area, provide optimum efficiency.

Splash fills maximize the water-surface-to-air interface. Instead of sheet surface, splash fills increase the water droplet surface. The splash fill breaks the water into smaller droplets, continually exposing more water surface to the airflow. The splash fill also allows the water to stay suspended allowing greater time exposure to the air. Historically, splashing fills have been made of a wood lath matrix or other forms of PVC or Polyethylene.

Made of polypropylene, it is resistant to attack from acids, alkalis, hydrocarbons, and biological and chemical attack. Opti-Grid contains UV inhibitors and can withstand continuous operating temperatures up to 180 ° F.

As an option, Opti-Grid is available with an ASTM E-84 rating of ≤ 25 using flame retardant additives.

High Efficiency

Non-Fouling Design

Maximum Strength