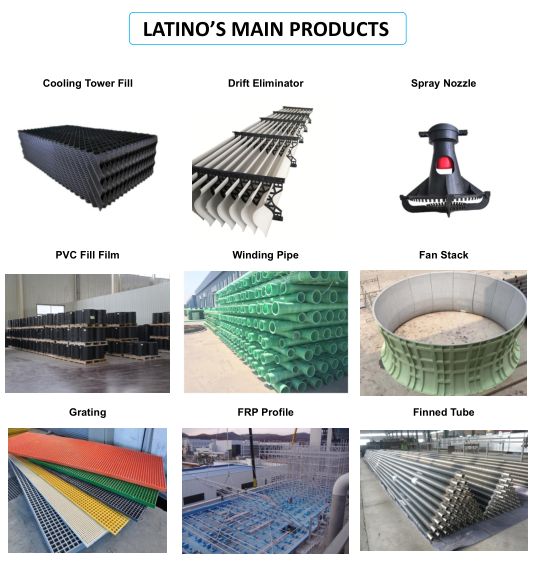

Cooling Tower Spray Nozzle

2021-08-26 18:39Why Are cooling tower Nozzles Important?

As everyone knows how important the cooling tower fill is to the cooling tower’s performance. Since cooling tower infill is the heat transfer media around which the “box” that is the cooling tower wasc built, you could argue that it’s the most important factor in determining just how well your cooling towers performs. However, since the cooling tower spray nozzles are tasked with getting the hot waterflow which was to been cool delivered to the fill, the nozzles also act a very important part in the duty of a tower. Cooling tower nozzles are involved in the following aspects of a cooling tower’s performance evaluation.

Water Distribution

The most obvious effect of the spray nozzle is due to its primary job of getting the hot waterflow to the fill. Ideally, the cooling tower spray nozzles are located and sized so that they provide the uniform pattern of water over the cooling tower fill with no gaps between their spray areas. You installed fill in the cooling tower, so now you need to make sure that you utilize it to its fullest extent by making sure that it is totally wetted out and all sections of fill receive a constant amount of water. All published performance data for a fill is based upon this assumption.

Gaps in spray coverage can lead to air bypass because dry fill offers lower resistance to airflow, and air will always take the path of least resistance. This will result in airflow being stolen from wet fill sections where it is needed to cool the hot water. Also, since air and water are both fluids, the gaps are not 100% constant in their location. As the competing fluids interact with each other they tend to pulse and shift around. This causes some of the fill to experience alternating cycles of wet and dry times which will promote scale formation within the fill. As scale builds up in a fill it starts to adversely affect its thermal performance capability, and in the extreme, can totally block airflow from the fill and potentially cause structural damage to the cooling tower if the fill’s weight gain from the scale is excessive.

Spray Zone

Another way that the spray system affects a cooling tower’s thermal performance is from the cooling that happens as soon as the water exits the nozzle and falls to the fill. The cooling effect in this spray zone can vary from 5-15% of the total cooling provided by the tower. The key to cooling here is to maximize the interaction between the hottest water and the coldest air. Thus, a nozzle that generates very small droplets will have a greater cooling effect than a nozzle that makes big, fat droplets. This is similar to the cooling effect of walking through a fine mist on a hot summer day as opposed to being hosed down by a fire hose.

Drift Eliminators

With ever-increasing scrutiny being paid to drift emissions from cooling towers, you have to be aware of the role that the nozzles can play on drift. Unfortunately, the fine spray of very small droplets that is beneficial from a cooling perspective creates a much more difficult challenge in preventing those same very small droplets from exiting the cooling tower as drift. This can be made even worse if the circulating water has very low surface tension due to water treatment that includes surfactants or due to compromised make-up water sources from wastewater treatment plants.