- Home

- >

- News

- >

- Cross flow tower

- >

Cross flow tower

2022-03-04 09:39Cross flow tower

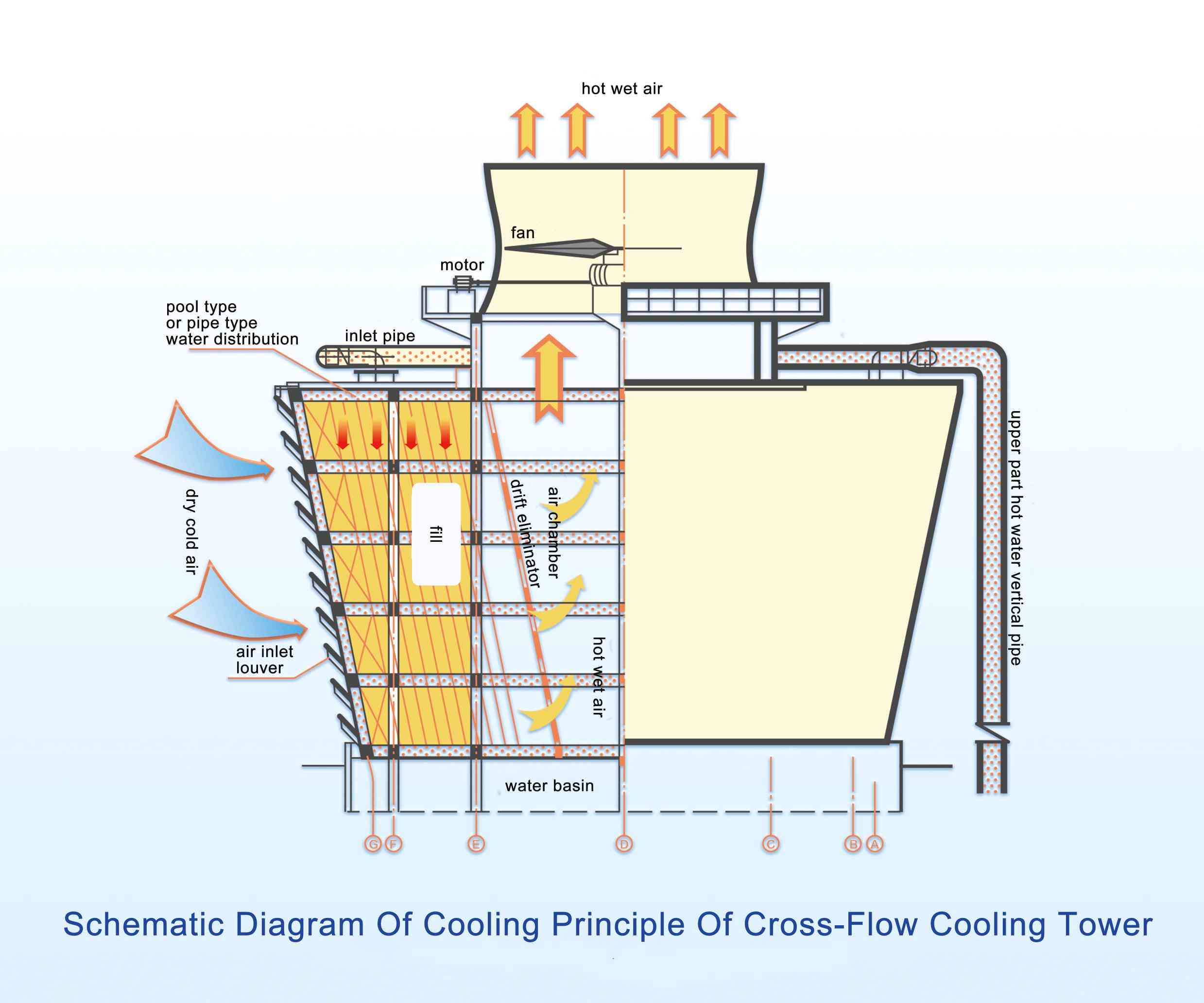

Cross flow tower is the abbreviation of cross flow cooling tower. Cross flow tower refers to the transverse inflow of air in the tower with the help of forced ventilation or natural ventilation of fan, while water droplets flow from top to bottom in the packing with the help of gravity. The flow direction of the two fluids is at an angle of 90 ° to carry out mass and heat transfer in the packing.

Principle:

The water in the cooling tower is cooled, and part of the heat is transmitted to the atmosphere due to the contact heat transfer formed by the temperature difference between water and air (the joint action of heat convection and heat conduction); Part of the heat is transferred to the atmosphere due to the surface evaporation of water (turning part of water into gas, diffusion and convection); In addition, some heat is also transferred from water to the atmosphere due to radiation, but the heat transferred by radiation is relatively small compared with the other two heat transfer forms, so it can be ignored in the thermal calculation of cooling tower. In short, the cooling process of the cooling tower is essentially the process of mass and heat transfer of cooling water.

Characteristic:

1. In the tower seasoning, the water flows from top to bottom, and the air flows horizontally from the tower to the tower, and the two flow directions are vertical and orthogonal. It is often used in residential areas with strict noise requirements. It is a cooling circulating tower widely used in the air conditioning industry. Advantages: energy saving, low water pressure, small wind resistance, also equipped with low-speed motor, no dripping noise and wind noise, and convenient maintenance of filler and water distribution system.

2. The foundation can be built randomly according to the shape of the building, and multiple cooling towers can be placed. Single or multiple cooling towers can be started according to the required water temperature.

3. It should be noted that the frame should be 40% more, and there should be more filler volume during heat exchange. The filler is easy to age, the water distribution hole is easy to be blocked, the anti icing effect is not good, and the moisture reflux is large.

Structure: