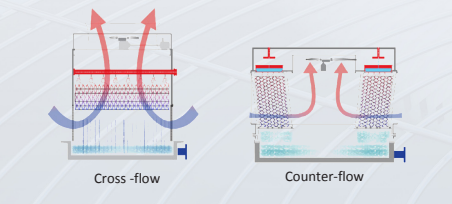

Difference between counterflow and crossflow cooling towers

2019-08-13 12:23Cooling towers can be classified in various ways. One of the basic dstinctions between them has to do with the direction of the air flow through the cooling tower fill inside of the cooling tower. When the air flow is contrary (180°) to the water flow, this kind of cooling tower is counterflow cooling tower, whereas when the air flow through the cooling tower fill is vertical (90°) to the water flow, this kind of cooling tower is the crossflow cooling tower.

The diagram shown below depicts the difference between these two kinds of cooling towers:

Direction of air flow and the cooling tower's structure

How the air flow in the cooling tower fill affects the cooling tower's structure

In the crossflow cooling towers, the water flows freely into the distribution basin ( not water basin) located in the upper part of the cooling tower. At the bottom of the distribution basin are hloes wherein cooling tower nozzles are installedthat distribute the water onto the cooling tower fill located beneath them. The water flows onto the cooling tower fill and is cooled ny the surrounding air, which is forced by the fan into the tower itself. The air, as aforementioned, flowshorizontally, perpendicular to the cooled water. The cooling tower fill type, its depth, and its height determine the degreeto which the water is cooled.

The fan in the crossflow tower can be of forced type( located on the side of the cooling tower) or induced type (located atop the tower). The tower can operate with a single distribution basin, called a dual-side tower.

In a counterflow cooling tower, the water enters into the cooling tower via closed, pressurized piping system ( usually not less than 0.2 atms). The entry into the tower is via a main header that split into two pipes of samller diameters, in each of which are installed cooling tower nozzle that convert the water flow into droplets.

In a counterflow cooling tower, the air enter the cooling tower via dedicated opening located below the cooling tower fill level. The air enters the space underneath the cooling tower fill, then changes direction and enters the cooling tower fill vertically, upwards, where it flows counter to the direction of the water that is sailing ( and not perpendicular thereto).

The air inlet location in a counterflow cooling tower crete a plenum underneath the cooling tower fill (following the air louver), as we as plenum over the cooling tower fill, between the fan stack and the drift eliminator layer.

Difference between counterflow and crossflow

These two aforementioned differences (differing water distribution, and lower and upper plenum) create differences in the properties of the two kinds of cooling towers:

* Foot print-Due to the plenum in the counterflow cooling towers, these towers for the most part have higher profiles and take up less land area tham do crossflow towers, for the same capacity(does not necessarily apply to site-erected towers).

* Tower height- For the same reason, a crossflow tower can be designed such that it is lower than a similar counterflow tower. This configuration can be appropriate for cooling towers located atop a building, where the height profile is architecturally significant, or in the case of a low ceiling, such as in a parking garge.

*Convenience of operation- The crossflow tower's structure is easier to maintain than that of a counterflow tower for the following two resaons:

Access tp distribution system. In a crossflow tower, access to the cooling tower nozzle( which are located in the distribution basin) is available at any given moment, giving the ability to check them, clean them, and replace them if needed; while in a counterflow tower, one must go inside the tower(which they cannot be done when the tower is in operation), where access to the sprayer is difficult.

Access into the tower plenum. In a crossflow tower, fitted with a inclued draft fan (atop the tpwer)- the standard configuartion- one can reach mid-plenum, located underneath the fan, while the tower is in operation. In this configuration, it is possible to examine and check drift eliminator layer and the mechanical system fro underneath; while a counterflow tower cannot be enter while it is om operation.

* Water supply- The form of gravitational distribution in a crossflow tower enables more operational fleibility and enables changing the cooling tower output flow more than does a counterflow. In general. the ourput in a crossflow tower can be increased/decreased by dozens of percentages simply by replacing the orifices intalled inside the gravitational nozzles. A counterflow tower offers less flexibility, as access to the sprayer ( and the sleeves) is more difficult.

*Water pressure- In principle, the water pressure needed crossflow cooling tower should be slightly less than that needed by a counterflow cooling tower, as in the latter, the pump must create enough pressure ( about 0.3 atms) for the distribution system to work. This extra pressure slightly increase the electricity conaumption of the pump in a counterflow tower.

*Exposure to light- The counterflow cooling tower is in most cases fitted with anti-light louvers that signofocantly block algar growth that results from sunlight, in turn decreasing the quantities of chemical need to treat it. In a crossflow tower (that is fitted with an induced-flow fan), the plenum underneath the fan is exposed to sunlight, and in order to cover it, a dedicated solution must be found (covering part of the exposed pool with a sealed platform, for example).

*Cold water- It is commonly claimed that crossflow cooling is more approprocate for cold climates (sub-zero temperatures), as it enables decreasing the quantity of water on the cooling tower fill surface by blocking some of cooling tower nozzle located closethe the fan thus, increasing the hydraulic load on the rest of the fill and decreasing the risk that the water will freeze; and enabling more precise forecasting of the tower's operation in such conditions.

*Noise- In counterflow towers, noise is produced as a result of the droplets falling the surface of the cold water basin. This noise can be muffled by a number of means, such as installing sound attemutaors at the air inlet or on top of the water. The problem is signigivantly redeuced at the outlet in crossflow cooling towers wherein the lower edge of the fill nearly touches the pool's surface.