FRP Structure Counterflow Cooling Tower Manufacture

2021-04-23 15:42FRP Structure Counterflow Cooling Tower Manufacture

Counterflow design cooling towers usually offer a smaller footprint than crossflow cooling towers and allow maximum thermal performance out of each plan area. Counterflow cooling towers also help minimize your pump head requirements. And, counterflow cooling towers are less likely to ice up in cold weather conditions.

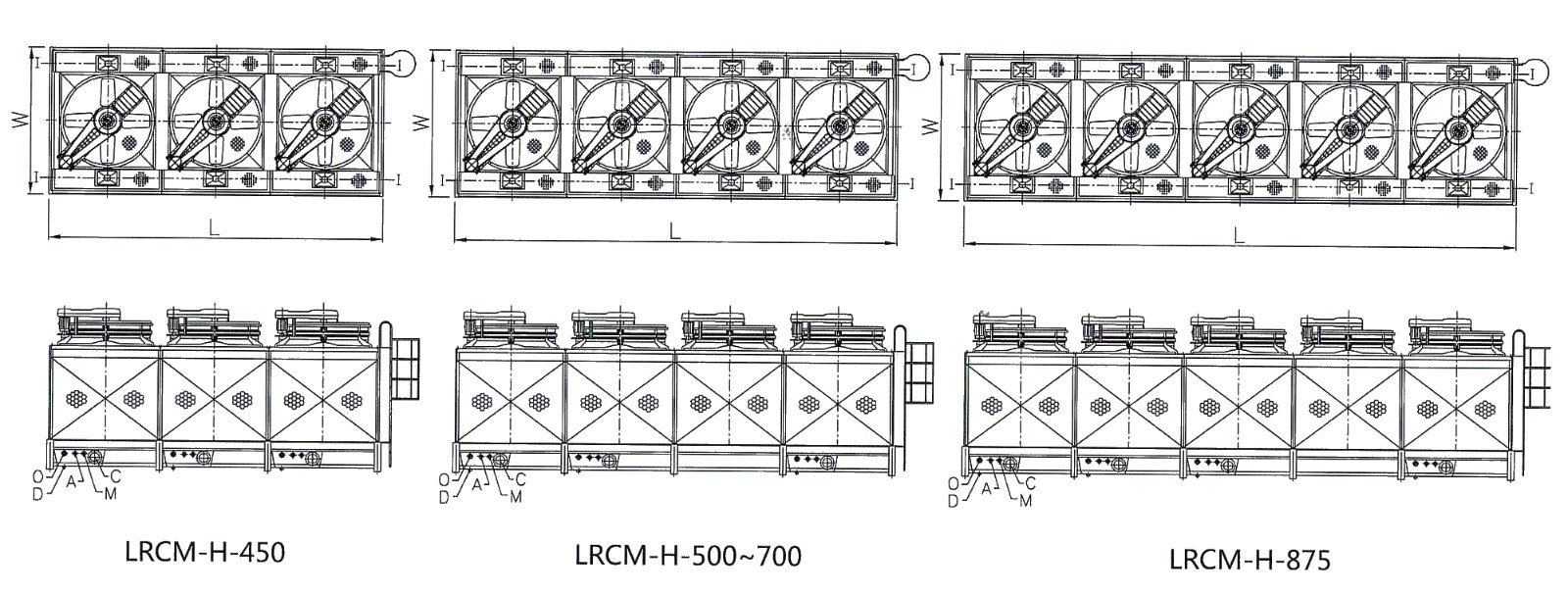

Latino Cooling Towers counterflow cooling towers are available in various cell sizes and various combinations of components, in order to meet your specific application requirements and offer you the most effective value.

Structural material choices include either wood or fiberglass composites.

Counterflow Towers At-a-Glance

Space-efficient design

Maximum thermal performance from given plan area

Can help minimize pump head requirements

Wide choice of models, cell sizes and components

Choice of wood or fiberglass composite structure

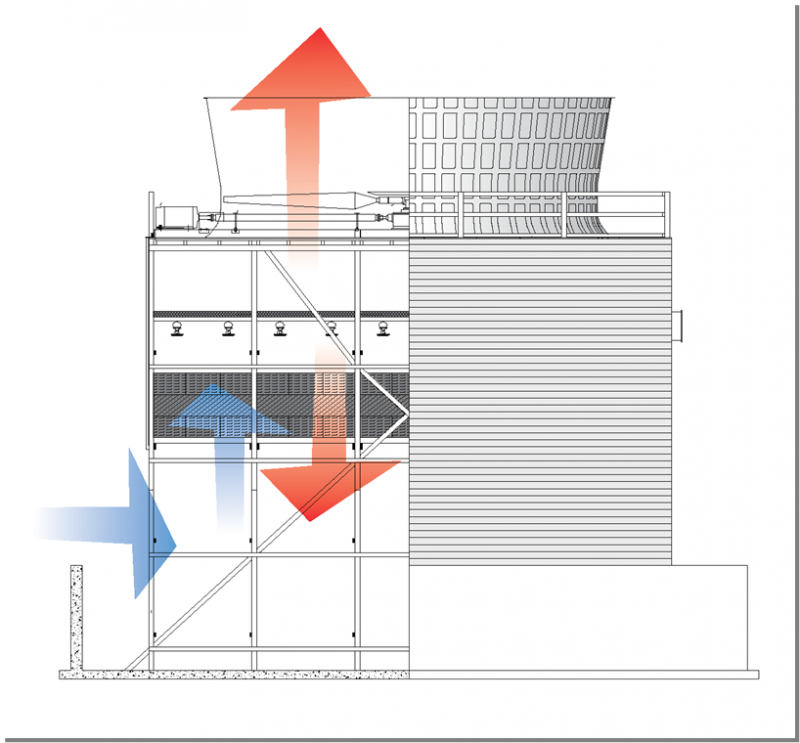

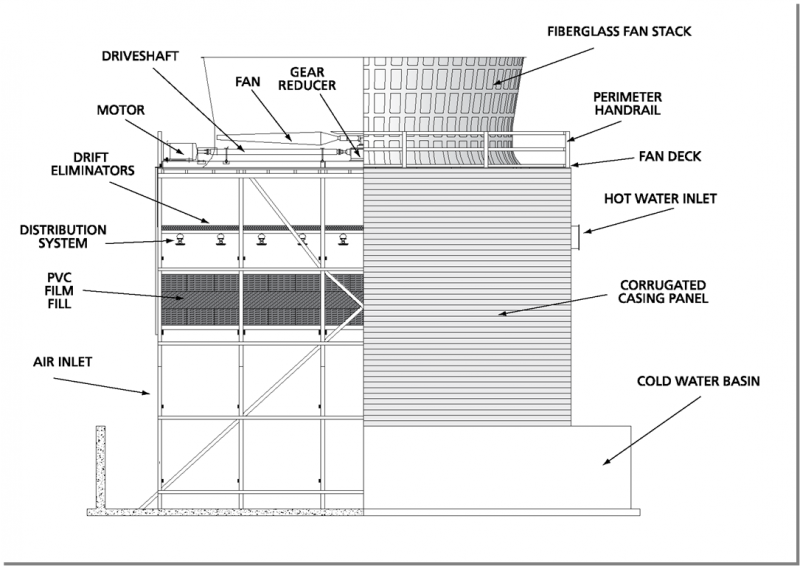

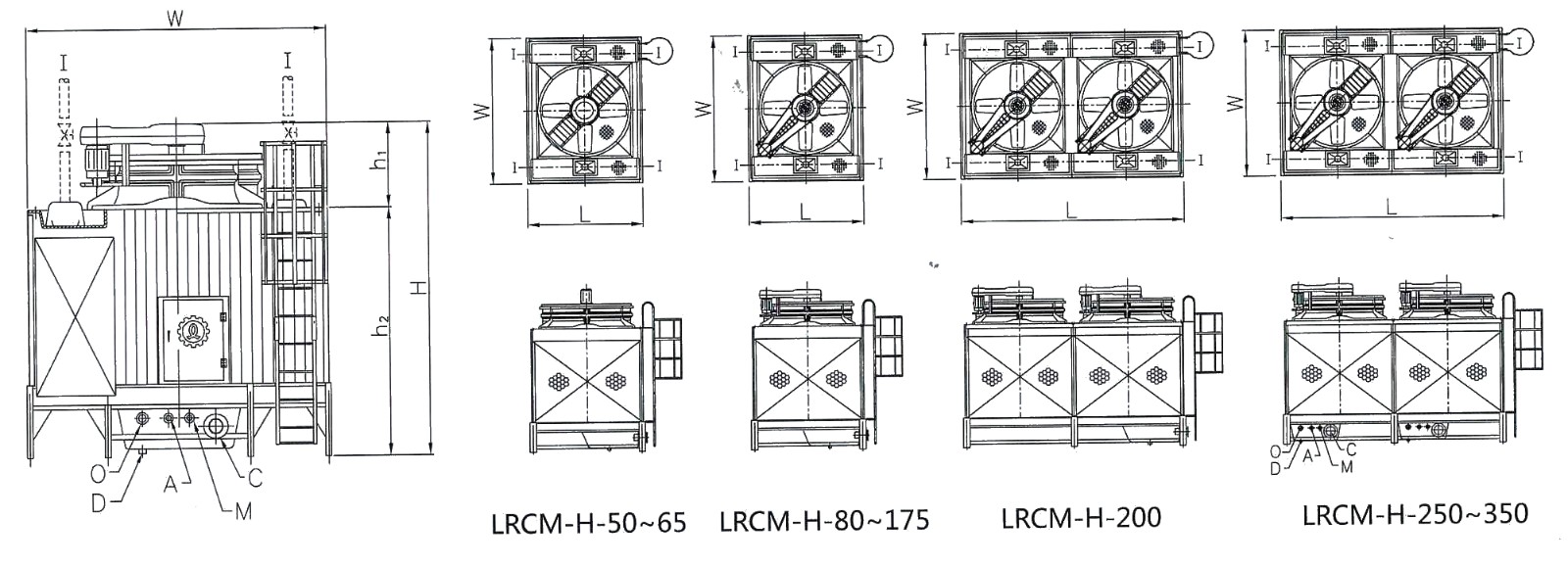

Counterflow Cooling Tower Diagrams

01- Technical Data Sheet

| Modle | water Flow m3/h | Fan Power kw(hp) | Dimensions (mm) |

| LNCM-10 | 10 | 0.75 | 1080*1080*2740 |

| LNCM-15 | 15 | 1.1 | 1280*1280*3500 |

| LNCM-20 | 20 | 1.5 | 1580*1580*3430 |

| LNCM-30 | 30 | 2.2 | 1880*1880*3840 |

| LNCM-40 | 40 | 3.7 | 2080*2080*3960 |

| LNCM-50 | 50 | 5.5 | 2400*2480*4600 |

| LNCM-65 | 65 | 7.5 | 2480*2480*4600 |

| LNCM-80 | 80 | 7.5 | 3080*3080*4900 |

| LNCM-100 | 100 | 7.5 | 3080*3080*4900 |

| LNCM-125 | 125 | 11 | 3480*3480*5250 |

| LNCM-150 | 150 | 11 | 3680*3680*5360 |

| LNCM-175 | 175 | 15 | 3680*3680*5470 |

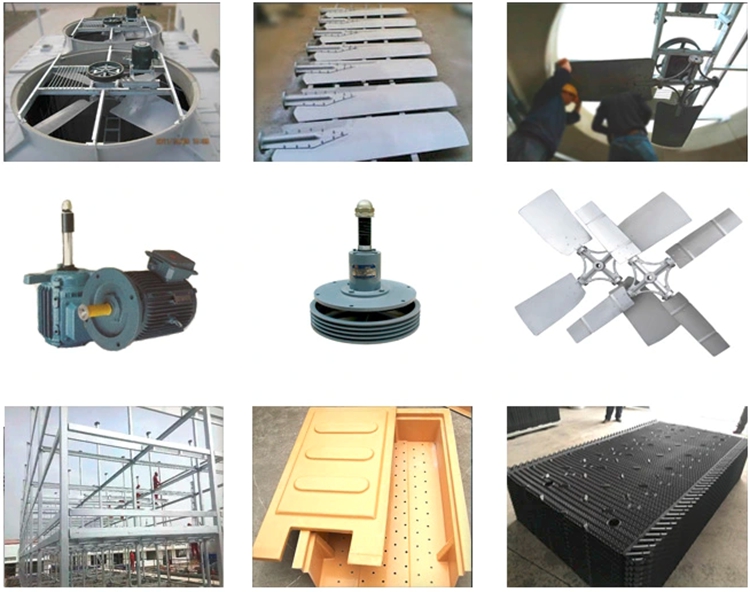

02- Liangchi Cooling Tower Accessories

03-Schematic Diagram

WORKING PRINCIPLE

1. Working fluid (water, oil or other flowing liquid) flowing inside of the coils, which is enwrapped by the cooling tower spray water on the outside. The heat of working fluid is transferred by the coil and become the saturated vapor when meeting the water and air.

2. The heat is exhausted out of the cooling tower by the cooling tower by the top fan; water is collected back to the bottom tank and circulates continuously. The cooling tower spray water is cooled down via cooling tower PVC fill in the process of circulation, and flow is the same direction with the fresh wind. The coil mainly takes sensible heat travel style.

3. The most benefit of this style is can avoid scale formation on the outside of the coil. And this will apply especially to dealing with high-temperature fluid (e.g. 60°C) or the fluid need big temperature difference (e.g. 60°C to 32°C).

Cooling tower body structure and performance

This fiber reinforced plastic cooling tower body is made of high-quality fiberglass reinforced plastics, the rubber coating surface of which is made of imported raw materials, which is even in color and will not fade or degrade easily.All structure parts made of steel are processed in hot-galvanizing.Injected molded parts are used widely for they are erosion-proof, high in intensity, light in weight and easy to attach.

The cooling tower has a successful water floating control, rendering a loss less than 0.001%.

-Use low-speed wind machine to avoid too much water spray in the air;

-Use waterproof sleeves on water distribution pipes to collect spilled water;

-The ground frame is larger than enclosure and is equipped with PVC shutters to avoid water spilling out of the tower.

Advantages

Low-noise control principle

Lower noise from the sound source.The special power machine is filled closed automatic cooling type low-noise cooling tower.Such kind of machine is good at water-proof performance, low in noise.

1.Low-speed fan to avoid excessive mist into the air.

2.FRP body contains stable materials resisting ultraviolet radiation with a long service life.

3.Filled with round counterflow model film.

4.Rotating pipe distributing model.

5.The structure contains rust-removing and high-strength galvanized steel which can bear corrosion and can be easily assembled.

6.Different types(standard,low-noise,high-temperature and industrial type) to meet your needs.

Main Features

1, Cooling tower is mainly used for cooling in air conditioning system, frozen series, injection molding, leather, foam, power generation, steam turbine, aluminum processing, air compressors, industrial cooling water and other fields;

2, Most used for air conditioning cooling, freezing, plastic chemical industry;

3, Closed circuit cooling tower have the Attractive shape: the Small dimension of shape, the low height of the tower, light weight of tower, and multiform layout in covering the area.