Industrial Cooling Tower Selection Features

2022-02-09 16:58Counterflow Cooling Tower:

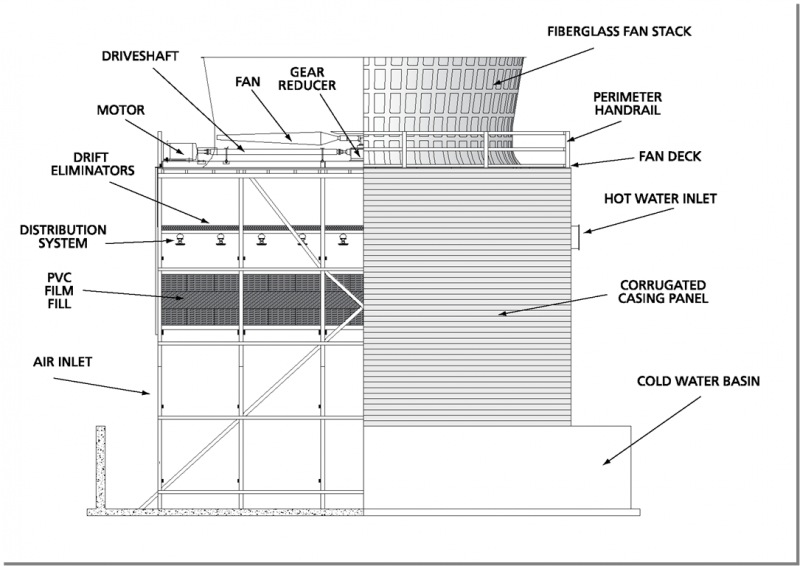

1. It occupies a small area and the structure of the cooling tower is simple, so the design, manufacture and construction are relatively simple. The water distribution system is enclosed in the cooling tower and not exposed to sunlight, so it is less likely to breed algae. Better heat exchange performance.

2. The exhaust cooling tower fans used are all multi-blade axial flow exhaust fans made

of aluminum alloy and glass wool reinforced plastic. After strict balance

correction, the operation is balanced and the noise is low. The angle of the

exhaust fan can be adjusted arbitrarily according to the actual required air

volume. .

3. The gear reducer adopts the helical helical gear specified by the CTI Cooling Tower Association. The V-belt has high tensile force, is tough and durable, runs quietly and is easy to maintain.

4. Transmission shaft: The probe is made of stainless steel or glass woven reinforced plastic, no need for lubricating oil, because there is no sliding, friction and rotating parts, no need to use lubricating oil, no noise, wear, large eccentricity allowable range, use can be The flexible (rain edge) drive shaft can increase the range of eccentricity. The thrust load and bending moment are small, which can reduce the reaction force generated by absorbing the shaft center while reducing the forward torque, no backlash, and high torsional rigidity. Good, easy to install and remove.

5. Using the ABS material cooling tower sprinkler, its advantage is low-pressure water-dispersing head with uniform water distribution, according to the amount of water, different apertures can be selected to effectively spread the cooling water evenly on the heat-dissipating material to exert the best cooling effect.

6. Using P.V.C vacuum forming cooling tower fill, the cooling water can be effectively attached to the surface of the heat sink material, so that the water flow speed is slowed down, the contact time between the water and the air is prolonged, and the heat exchange efficiency is increased.

7. Cooling tower drift eliminator: Use a high-efficiency cooling tower drift eliminator, and the small water droplets must be folded 3~4 times to form an effective water blocking effect.

8. All structures are made of wood and hot-dip galvanized iron or stainless steel or reinforced concrete that have been treated with vacuum pressure anti-corrosion.

9. A single unit can handle a large amount of water, and can be used in parallel at any time to meet the needs of the site and cooling capacity.