Multi-layer Filter For Oil Water Separate

2020-05-14 16:51

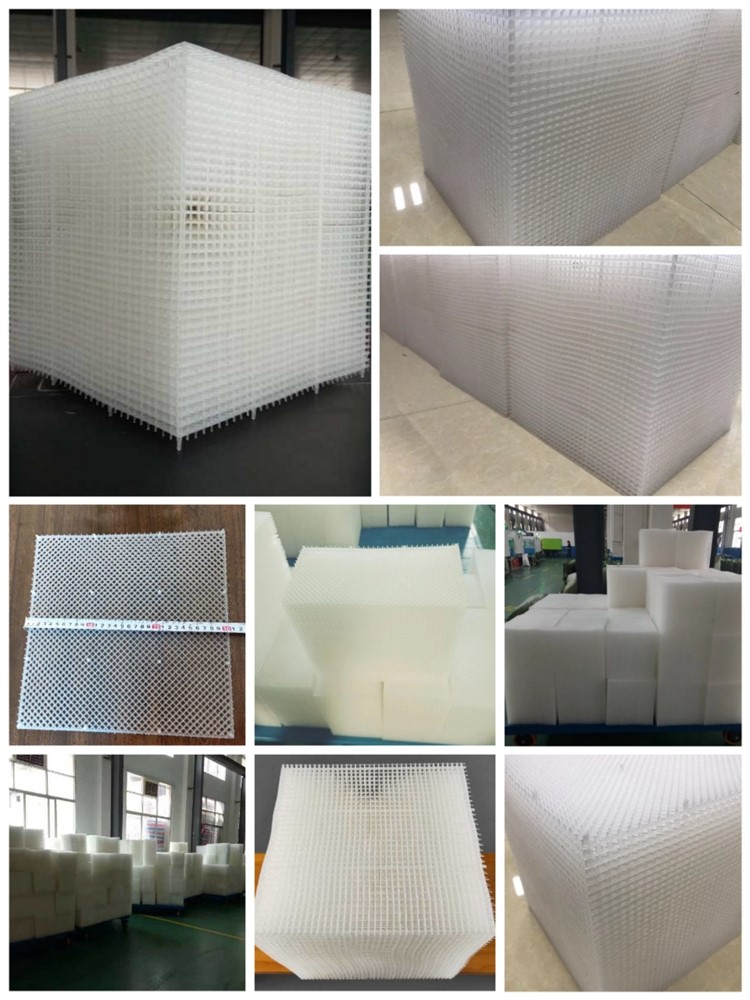

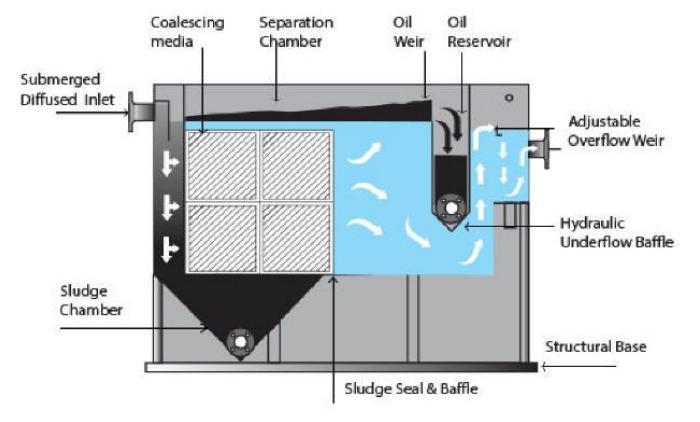

The Multi-layer Filter For Oil Water Separate(OWS) contains a coalescing medium or media. This media provides a suitable surface for oil droplets to meet and grow, or coalesce, into larger droplets. As oil droplets grow in size the buoyancy of the droplets increase. The droplets rise towards the surface of the water due to the fact that the specific gravity of oil is less than the specific gravity of water. In this way the oil will form a layer that can be separated from the water by skimming action before the water is reused or discharged. Any heavy solids present in the water being treated, or sludge, in theory should fall into the sludge compartment of the OWS unit. As oil droplets coalesce into to larger droplets, the buoyancy of the droplets increases. This is reflected in the known rise time for a given size of oil droplet. The more efficient the coalescence action of the media, the larger the oil droplets become.

Traditional coalescing media have been variations of corrugated, inclined plates. By definition half of the surface of this type of media must always be aligned upward – which is the wrong direction for support of coalescing action. To attempt, in part to overcome this problem by adding more specific surface, plate separation can be made more narrow. This solution only solves the problem partially as the ratio of incorrect to correctly oriented surface remains 50/50. But as the spacing of the plates narrows, plugging of the coalescing media – and hence the failure of the OWS unit – becomes more likely.

One advantage of using polypropylene is that the OWS can operate with a water temperature to 200 degrees F (93 degrees C) vs. the cheaper corrugated medias which are made from PVC and begin to weaken at 120 degrees F (49 degrees C).

With all rounded elements, the entire surface area of 132 ft2/ft3 (433m2/m3) of HD Q-PAC is available to support oil droplet coalescence. As a result, there is no need for any type of 2nd stage polishing to achieve needed oil removal.

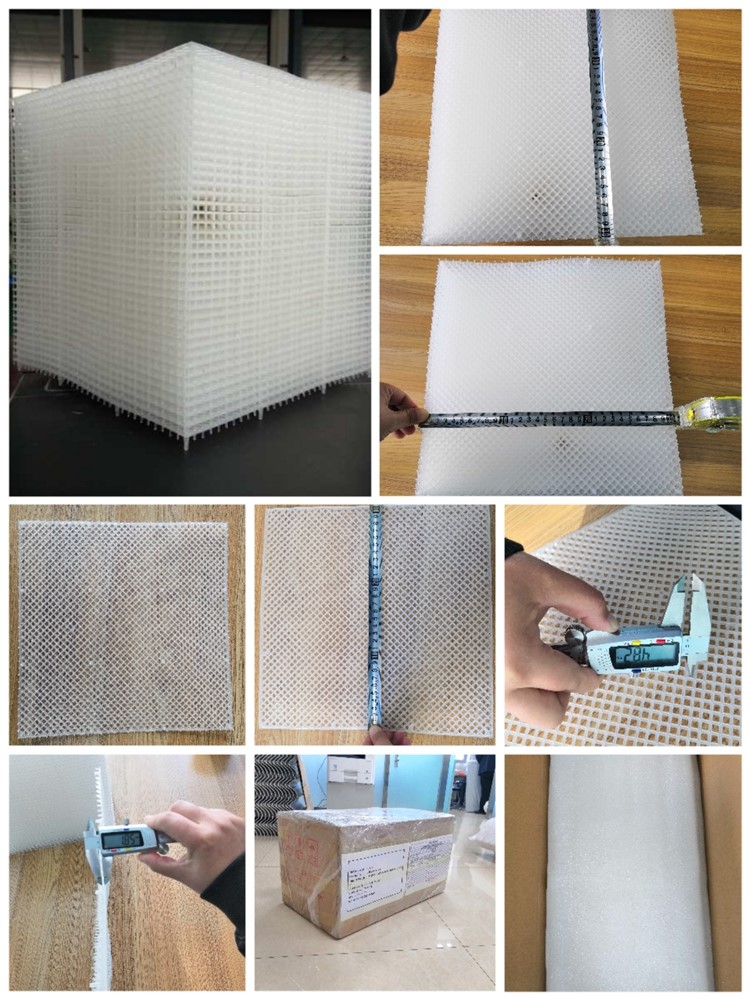

Technical Data For Multi-layer Filter For Oil Water Separate:

Size mm | Surface Area ft2/ft3 | Drip Points | Bulk Density kg/m3 | Smallest Grid Opening | Void Ratio % |

| 305*305*305 | 132 | 75000/ft3 | 7.5 lb/ft3 | 0.16''*0.16'' | 87.8% |

| 40*40*40 | 612m2/m3 | No Data | 170 kg/m3 | 0.07''*0.07'' | No Data |

Tianjin LATINO Environmental Technology Co., Ltd. are on the base of high quality, good service, we win good reputation in the industry. We help our customers better to get cooling tower products from China.We specializes in manufacturing various cooling tower and parts. Our company's cooling tower products is being used widely around the world. Our business involve in Italy, Germany, Australia, UK, Indonesia, Thailand, Belgium, France, Poland, India, Malaysia, Singapore and New Zealand, etc..

Latino has a high quality team of talents. Team members are young and energetic, with a sense of innovation and the courage to meet the challenge.Team members develop and practice new e-marketing mode, follow consumer demand, provide customers with high quality products and services.

LATINO has an experienced team in quality and project implement to support the purchasing activities of overseas customers;The company's main products are cooling tower parts, such as Film Fill, drift eliminator and spray system, UPVC distribution pipes, FPR winding splash pipe, FRP profile parts,FRP gratings, Fan stack, band & clamp, etc.; Our product are approved by CTI and we have our own patent .

Our factory has the largest capacity and have been working with the recognized brands of cooling tower in around the world, our team have rich experience in oversea projects.we were your colleague, knowing your care, your culture and your requirements.So we make it easy for you to purchase high quality and good value internal plastic parts of cooling tower in China.

Our fill has been verified by actual operation for more than ten years. It is very reliable and efficient. You can rely on us to deliver a successful project while reducing your total project costs!