Omega Bar Fill For Marley Cross Flow Cooling Tower

2022-01-13 17:58Omega Bar Fill For Marley Cross Flow Cooling Tower

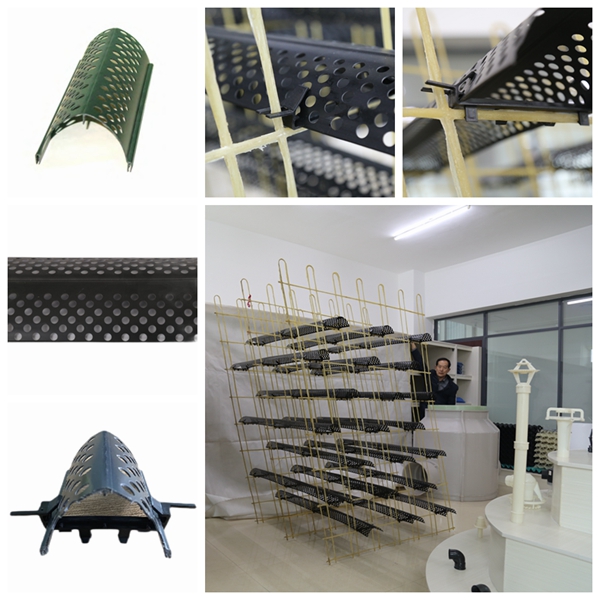

Marley Omega splash fill provides a robust, cost effective solution for crossflow cooling towers.

Variable fill bar spacings provide the required thermal performance with the minimum amount of fill material and installation time. Omega fill is installed in a parallel to the air flow configuration.

Omega fill bars are made by corrosion resistant PVC (polyvinyl chloride). The unique material formula used in the Omega bar meets or exceeds CTI Standard 136 for strength, flammability and impact. Each bar is firmly attached to the polypropylene grid. Alternate methods of attachment can be stainless steel or vinyl coated steel wire grids with unique injection molded polypropylene benches designed to prevent premature wear on the fill bar.

Omega bar's classic arch shape enhances structural characteristics which prevents sagging, even after prolonged exposure to cooling tower environments. Omega fill and its support system are designed to be used in virtually all cooling towers regardless of a cooling tower’s age or manufacturer.

The fill will be used in crossflow cooling towers. Construction and Materials Each fill bar will be a PVC extrusion, designed to prevent excessive sagging between support points. The bars will be supported in an injection molded polypropylene grid. The grid will be designed to maintain the fill bars in proper vertical and horizontal spacing. Each bar will be retained integrally by the grid to prevent premature wear.

Configuration

Fill bar spacing will be determined by the vendor as necessary for the required thermal performance. Each bar will have an arch shape. The sides of the arch will be perforated at regular intervals to develop proper water break-up.

Latino's main products