- Home

- >

- Products

- >

- Fiberglass Grating

- >

Fiberglass Grating

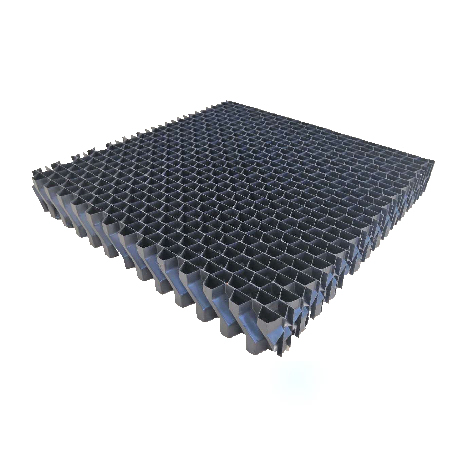

Fiberglass Grating is made of thoroughly wetted continuous glass strand fibers and a special resin which provides the maximum corrosion resistance to chemicals.

Surface: flat,concave,sanding,covered and so on.

Fiberglass Grating is widely used in the cooling tower, oil industry, power engineering, water & waste water treatment as working floor, stair tread, trench cover, etc. It is an ideal loading frame for corrosion circumstances.

- LATINO

- CHINA

- 3 WEEK

- 300 CUBIC METER

- Information

- Video

- Download

Fiberglass Grating

Molded fiberglass grating is manufactured by laying continuous glass fibres in the mould in the direction of vertical and horizontal, and througly wetted out with resin, layer by layer. When the weaving process is completed, the mould is heated to cure the panel. After curing, the panel is ejected from the mould. The standard panel would have meniscus (concave) top surface. Any process such as post applied grit could be bonded after as a secondary operation. This continuous process produces an integral, one piece panel, which offers excellent corrosion resistance as well as bi-directional strength.

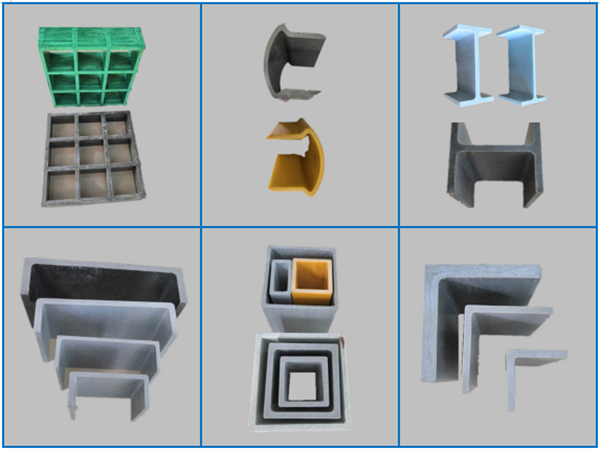

Fiber reinforced plastic (FRP), also known as fiber reinforced polymer, is in fact a composite material constituting a polymer matrix blended with certain reinforcing materials, such as fibers. The fibers are generally basalt, carbon, glass or aramid; in certain cases asbestos, wood or paper can also be used.

Most of these plastics are formed through various molding processes wherein a mold or a tool is used to place the fiber pre-form, constituting dry fiber or fiber containing a specific proportion of resin. After ‘wetting’ dry fibers with resin, “curing” takes place, wherein the fibers and matrix assume the mold’s shape. In this stage, there is occasional application of heat and pressure. The different methods include compression molding, bladder molding, mandrel wrapping, autoclave, filament winding, and wet layup, amongst others.

The other exclusive properties of fiber reinforced plastics include commendable thermal insulation, structural integrity, and fire hardness along with UV radiation stability and resistance to chemicals and other corrosive materials.

The characteristics of fiber reinforced plastics are dependent upon certain factors like mechanical properties of the matrix and fiber, the relative volume of both these components, and the length of the fiber and orientation within the matrix.

Application:

1. Chemical & Petrochemical Plants

2. Food & Beverage Plants

3. Power Plants

4. Water Treatment Plants & Water Pools

5. Ramp, Scaffold, Railway Footpath

6. Operating Platforms & Trench Covers

7. Walkways, Footbridges & Staircase

Excellent properties

1) corrosion/slip resistant 2) fire/impact retardant 3) high strength-to-weight ratio 4) easy to install and to maintain

LATINO has an experienced team in the quality and project implement to support the

purchasing activities of overseas customers;The company's main products are

cooling tower parts, such as Film Fill, drift eliminator and spray system, UPVC

distribution pipes, FPR winding splash pipe, FRP profile parts,FRP gratings, Fan

stack, band & clamp, etc.; Our product are approved by CTI and we have our

own patent .

LATINO has an experienced team in the quality and project implement to support the

purchasing activities of overseas customers;The company's main products are

cooling tower parts, such as Film Fill, drift eliminator and spray system, UPVC

distribution pipes, FPR winding splash pipe, FRP profile parts,FRP gratings, Fan

stack, band & clamp, etc.; Our product are approved by CTI and we have our

own patent .

For more informations, please kindly visit the following website:http://www.tianjinlatino.com

Recommend Products

Our Company

Tianjin LATINO Environmental Technology Co., Ltd. are on the base of high quality, good service, we win good reputation in the industry. We help our customers better to get cooling tower products from China. We specializes in manufacturing various cooling tower and parts. Our company's cooling tower products is being used widely around the world. Our business involve in Italy, Germany, Australia, UK, Indonesia, Thailand, Belgium, France, Poland, India, Malaysia, Singapore and New Zealand, etc..

Latino has a high quality team of talents. Team members are young and energetic, with a sense of innovation and the courage to meet the challenge.Team members develop and practice new e-marketing mode, follow consumer demand, provide customers with high quality products and services.

LATINO has an experienced team in quality and project implement to support the purchasing activities of overseas customers;The company's main products are cooling tower parts, such as Film Fill, drift eliminator and spray system, UPVC distribution pipes, FPR winding splash pipe, FRP profile parts,FRP gratings, Fan stack, band & clamp, etc.; Our product are approved by CTI and we have our own patent .

Our factory has the largest capacity and have been working with the recognized brands of cooling tower in around the world, our team have rich experience in oversea projects.we were your colleague, knowing your care, your culture and your requirements.So we make it easy for you to purchase high quality and good value internal plastic parts of cooling tower in China.

Our fill has been verified by actual operation for more than ten years. It is very reliable and efficient. You can rely on us to deliver a successful project while reducing your total project costs!