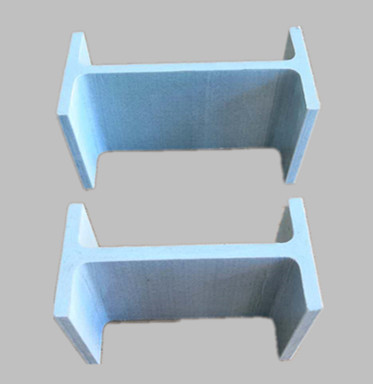

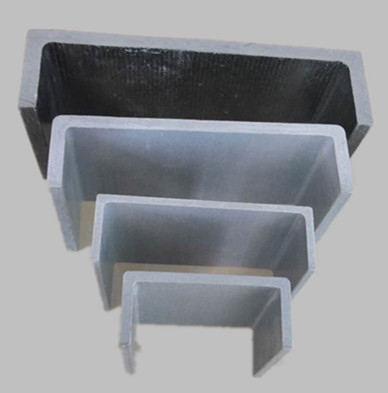

FRP Pultruded Sections

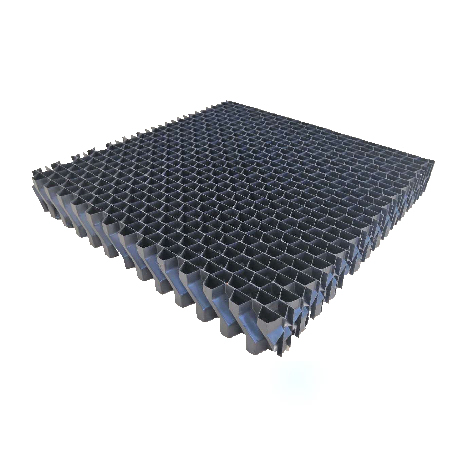

FRP Pultruded Section is the manufacturing process for producing the continuous lengths of reinforced polymer structural shapes with the constant cross-sections. The raw materials are a mixed liquid resin (including resin, fillers and specialized additives) with flexible textile reinforcing fibers. The process is pull these raw materials by a heated steel forming die using a special continuous pulling device.

The FRP Pultruded Section are in continuous forms, such as the rolls of fiberglass mat and doffs of fiberglass roving. As the reinforcements are been saturated with the resin mixture in the resin bath and pulled through the die, the gelation, or hardening, of the resin is initiated by the heat from the die and a rigid, cured profile is formed that bsed on the shape of the die.

- LATINO

- CHINA

- ONE MONTH

- BASED ON REQUEST

- Information

- Video

- Download

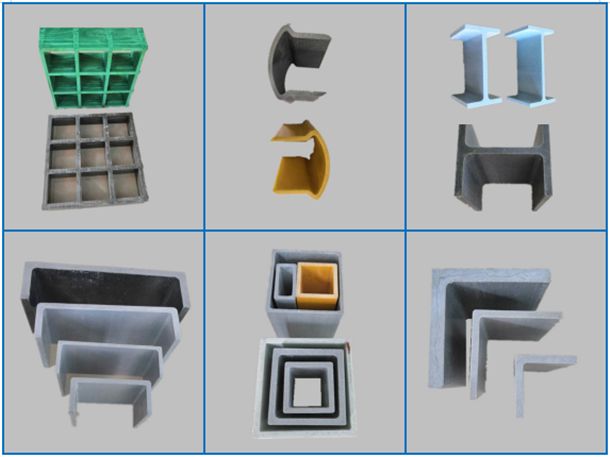

FRP Pultruded Sections

Fiber reinforced plastic (FRP), also known as fiber reinforced polymer, is in fact a composite material constituting a polymer matrix blended with certain reinforcing materials, such as fibers. The fibers are generally basalt, carbon, glass or aramid; in certain cases asbestos, wood or paper can also be used.

Most of these plastics are formed through various molding processes wherein a mold or a tool is used to place the fiber pre-form, constituting dry fiber or fiber containing a specific proportion of resin. After ‘wetting’ dry fibers with resin, “curing” takes place, wherein the fibers and matrix assume the mold’s shape. In this stage, there is occasional application of heat and pressure. The different methods include compression molding, bladder molding, mandrel wrapping, autoclave, filament winding, and wet layup, amongst others.

The other exclusive properties of fiber reinforced plastics include commendable thermal insulation, structural integrity, and fire hardness along with UV radiation stability and resistance to chemicals and other corrosive materials.

The characteristics of fiber reinforced plastics are dependent upon certain

factors like mechanical properties of the matrix and fiber, the relative volume

of both these components, and the length of the fiber and orientation within the

matrix.

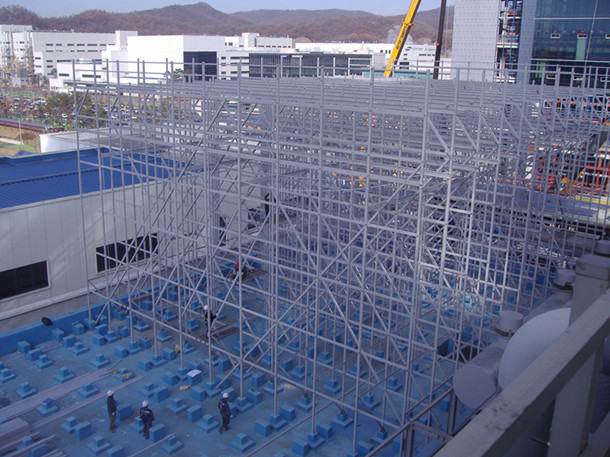

Application at site

For more informations, please kindly visit the following website:

Tianjin Latino Environmental Technology CO.,Ltd is a scientific-oriented economy body integrating with scientific research, designing, manufacturing, installation and service maintenance, which is originated from European. We, Tianjin Latino are specialized supply one stop service for the cooling tower parts and cooling tower engineer service.

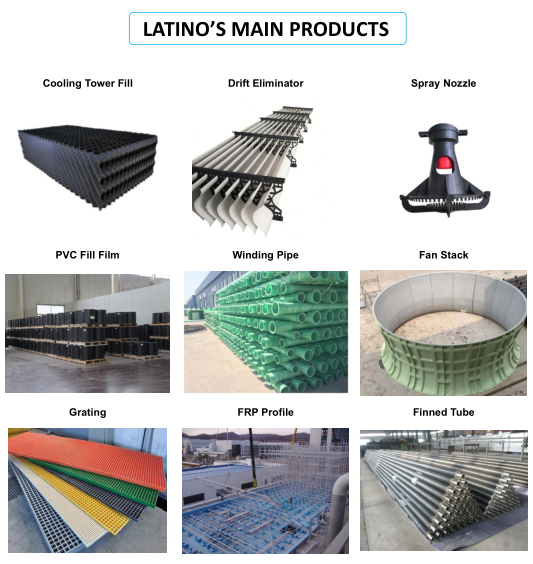

Tianjin Latino’s main products are cooling tower, cooling tower Film Fill, cooling tower drift eliminator and cooling tower spray system, UPVC distribution pipes, FPR winding pipe, FRP profile parts,FRP gratings, Fan stack, etc. Tianjin Latino's cooling tower and cooling tower parts is being used widely used in the world. Our business involve in UK, Germany, Italy, Belgium, France, Poland, Israel, Russia, Turkey, UAE,IRAN, Malaysia,Philippines, Indonesia, Korea, Japan, Australia, Thailand, India, Singapore and New Zealand, Netherlands,Ukraine, etc..

Tianjin LATINO has an experienced team in quality and project implement to support the purchasing activities of overseas customers. Based on the superior design , professional service, Tianjin Latino’s cooling tower and cooling tower parts is widely used in the Petrochemical, Petroleum, Power, Metallurgy, Medicine and Rubber Industry, etc..

We aim to help all of the customers choose the suitable cooling tower parts from China with competitive price easily. and have the capacity to support every potential customer to be our sales agent successfully! We have good reputation int the cooling tower industry, based our superior quality, professional service.

Tianjin Latino Environmental Technology CO.,Ltd is a scientific-oriented economy body integrating with scientific research, designing, manufacturing, installation and service maintenance, which is originated from European. We, Tianjin Latino are specialized supply one stop service for the cooling tower parts and cooling tower engineer service.

Tianjin Latino’s main products are cooling tower, cooling tower Film Fill, cooling tower drift eliminator and cooling tower spray system, UPVC distribution pipes, FPR winding pipe, FRP profile parts,FRP gratings, Fan stack, etc. Tianjin Latino's cooling tower and cooling tower parts is being used widely used in the world. Our business involve in UK, Germany, Italy, Belgium, France, Poland, Israel, Russia, Turkey, UAE,IRAN, Malaysia,Philippines, Indonesia, Korea, Japan, Australia, Thailand, India, Singapore and New Zealand, Netherlands,Ukraine, etc..

Tianjin LATINO has an experienced team in quality and project implement to support the purchasing activities of overseas customers. Based on the superior design , professional service, Tianjin Latino’s cooling tower and cooling tower parts is widely used in the Petrochemical, Petroleum, Power, Metallurgy, Medicine and Rubber Industry, etc..

We aim to help all of the customers choose the suitable cooling tower parts from China with competitive price easily. and have the capacity to support every potential customer to be our sales agent successfully! We have good reputation int the cooling tower industry, based our superior quality, professional service.