Industrial Closed Circuit Industrial Water Cooling Tower Manufacture

Industrial Cooling Tower is widely used in industries of Electric Power, Petroleum, Chemical Engineering, Chemical Fertilizer, Smelt, etc. Cooling water capacity ranges from 800 m3/h - 4000 m3/h. According to Customers' request, we also supply high temperature type, sewage type, and also designed to different shape to match with the customer's site location.

- LATINO

- CHINA

- 3 MONTH

- 100 SET ONE MONTH

- Information

- Video

- Download

Industrial Closed Circuit Industrial Water Cooling Tower Manufacture

Latino manufactures a large variety of cooling tower that can be used for both industrial and civil perposes.

The capacity ans the style of the cooling tower vary, one cell capacity rangs from 5 m³/h to 6000m³/h, tower shape range from quadrate, round to polygons, structure includes steel structure, concrete structure and FRP structure. Tpwer type ranges from cross flow cooling tower to counter flow cooling tower, from mechanical draft to natural draft, from forced draft to induced draft, from clear water tower to turbid water tower.

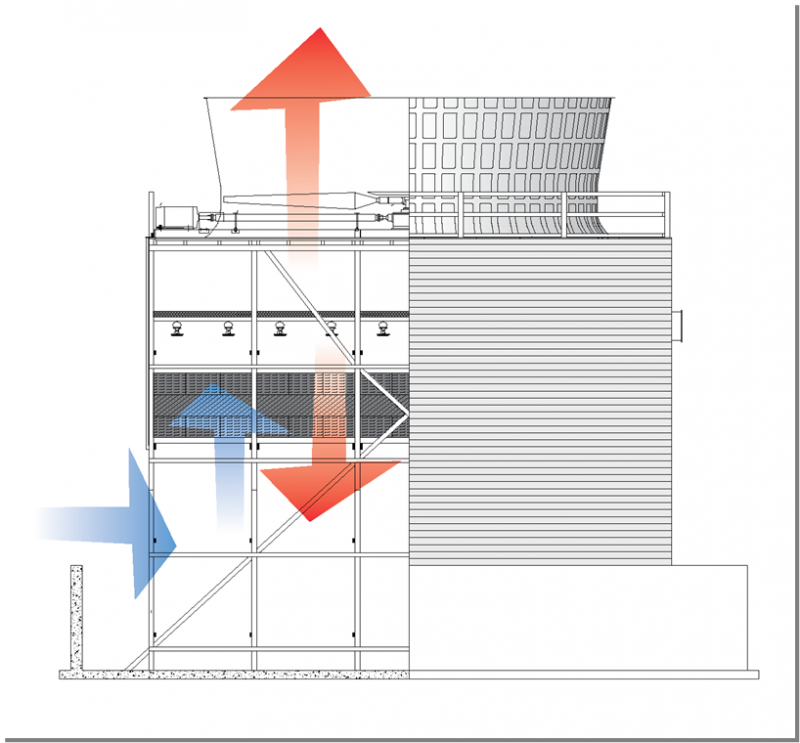

Process principle:

The air intake style is inlet from the bottom of the tower,which is a lternating direction interative with the fall down spray water and form to saturated vapor in the process.the heat is exhausted out of tower by the fan and the water is collected to bottom tank and circulate continuously by the special evaporator.there is no heat sinking fillings inside of the tower,so more space is saved to increase coil sradiating area.tight structure lead tolittle area take up.this apply especially to dealing wih low temperature fluid.

Product characteristics

1.tight structure

reducing the space of heat exchange stuffing makes the equipment much tighter less occupied space and convenient for shipping and installation.it is more suitable for severe enviroment,such as steel plant,foundry,and all kinds of mine plants,etc.

2.elliptical tube design

compared with round tube,using elliptical tube as heat exchanger coils can make the form tighter,less filling tate of liquid and less air flow resistance.

3.precooling fin design

we can increase the precooling fin on the cooling tower,precooling of high temperature or stop the water at low temperature.more suitable for serious water shortage area.

Counter flow series principle of operation

1.water is pumped over the evaporative coil at a 6.9L/S of coil face area to ensure continuous flooding of the primary heat transfer surface which enhances heat transfer efficiency and minimizes fouling and scale formation.

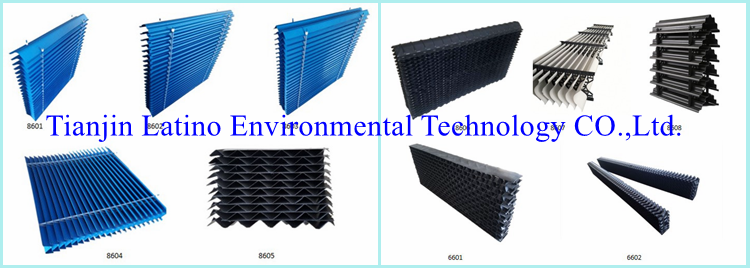

2.high-effective water eliminater is made of PVC,can filter the drips from expelted airsteams.radiation-enduring and long lifespan.with the access door on the eliminators side panels.

3.easy removable air inlet grating avoids sun projectivity dust and dirt coming in.

4.for applications that might deposit soluble scale or sludge tithin the tubes,the cleannable header tube bundle provides removable cover plates.

Industrial Cooling Tower is widely used in industries of Electric Power, Petroleum, Chemical Engineering, Chemical Fertilizer, Smelt, etc. Cooling water capacity ranges from 800 m3/h - 4000 m3/h. According to Customers' request, we also supply high temperature type, sewage type, and also designed to different shape to match with the customer's site location.

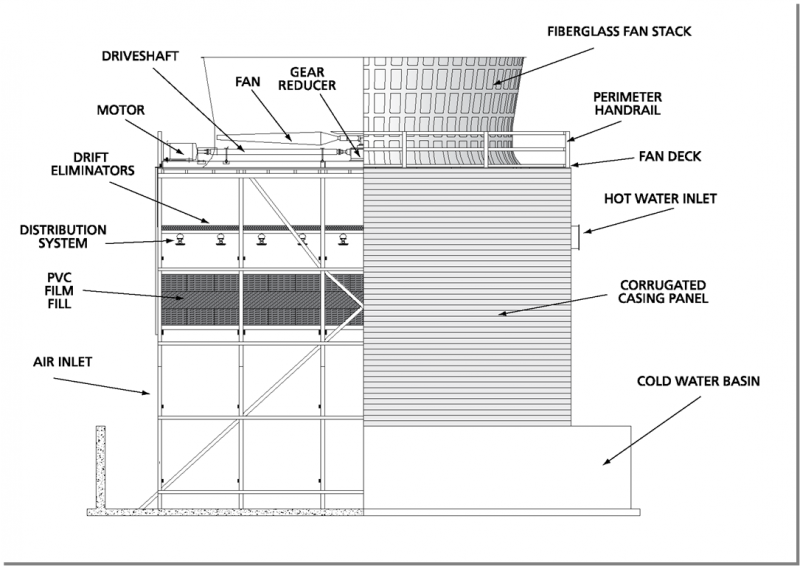

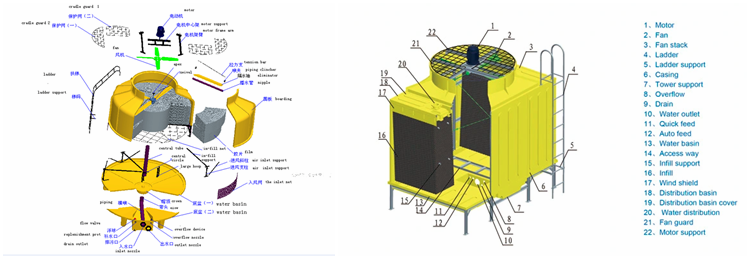

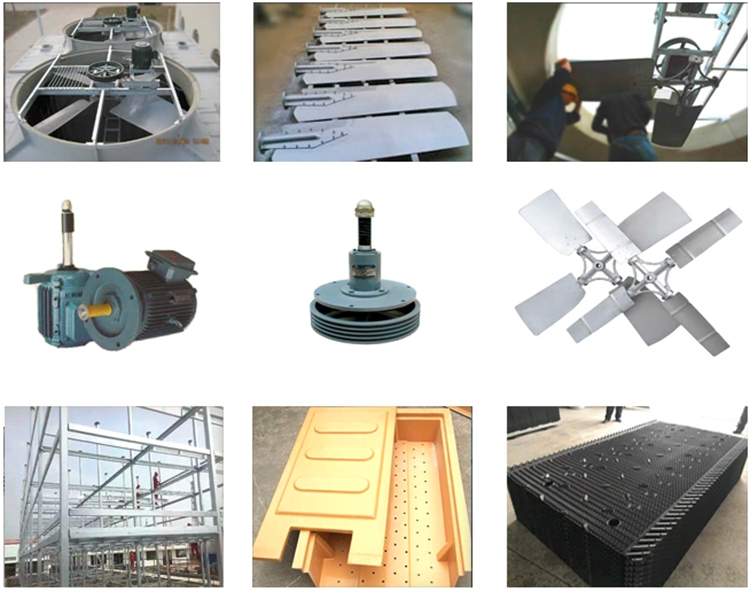

Components Instruction

Tower framework

It is made of steel, pipe and square tube, etc to composed of a space frame, taken effective anti-corrosion measures for components, overall stability, good rigidity.

Fan stack

F.R.P material, with steel tension bar and protector, and includes reasonable aerodynamic performance design, to make the Fan stank great strength and high efficiency.

Cooling tower spray system

Used pipe distribution, distribution nozzle is imported USA DESP's technology, its salient features is gravity without pressure, spraying water as uniform square, adjustable spraying area, which made the cooling tower water distribution more reasonable, but also greatly reduce the energyconsumption of cooling tower.

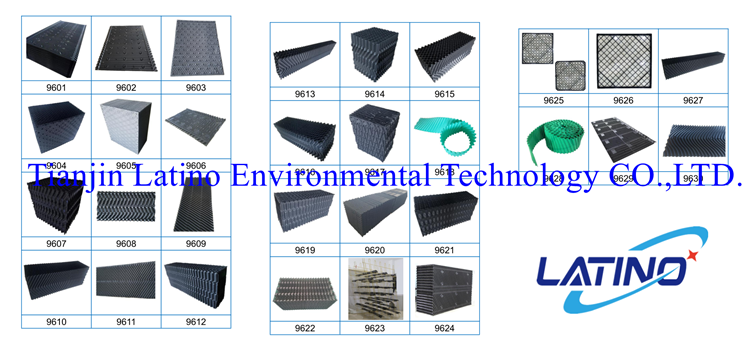

Cooling Tower Infill

Used 100% raw material sheet PVC material infill, its unique twill design and honeycomb structure, which made high efficiency of heat exchange. According to customers' request and circulation water condition, other type of infill could be supplied.

Howden Brand Fan Assembly

The Howden D-Series is a highly efficient cooling fan which combines the highest aerodynamic performance with very low power consumption. Large air volume, high efficiency, low noise, corrosion resistant.

Motor

ABB / SIMENS brand motor,IP55,Class F

Gear Reducer

Sumitomo reducer, horizontal, low noise, high efficiency and reliable lubrication, maintenance is convenient, equipped with oil moderate vibration alarm device. The service factor: 2.0

Murphy Brand Vibration Switch

Original imported Murphy brand vibration switch ensure the stable and long term reliable service life.

Control and Energy Saving

VFD control

Two-speed motor

Reversible cooling fan

Remote control, Promote reset

Earthquake prevention level: M8.0

Typhoon prevention level: L 13

Relevant cooling tower components:

1. Cooling tower PVC fill

2. Cooling tower spray nozzle

3. Cooling tower drift eliminator

Tianjin LATINO Environmental Technology Co., Ltd. are on the base of high quality, good service, we win good reputation in the industry. We help our customers better to get cooling tower products from China.We specializes in manufacturing various cooling tower and parts. Our company's cooling tower products is being used widely around the world. Our business involve in Italy, Germany, Australia, UK, Indonesia, Thailand, Belgium, France, Poland, India, Malaysia, Singapore and New Zealand, etc..

Latino has a high quality team of talents. Team members are young and energetic, with a sense of innovation and the courage to meet the challenge.Team members develop and practice new e-marketing mode, follow consumer demand, provide customers with high quality products and services.

LATINO has an experienced team in quality and project implement to support the purchasing activities of overseas customers;The company's main products are cooling tower parts, such as Film Fill, drift eliminator and spray system, UPVC distribution pipes, FPR winding splash pipe, FRP profile parts,FRP gratings, Fan stack, band & clamp, etc.; Our product are approved by CTI and we have our own patent .

Our factory has the largest capacity and have been working with the recognized brands of cooling tower in around the world, our team have rich experience in oversea projects.we were your colleague, knowing your care, your culture and your requirements.So we make it easy for you to purchase high quality and good value internal plastic parts of cooling tower in China.

Our fill has been verified by actual operation for more than ten years. It is very reliable and efficient. You can rely on us to deliver a successful project while reducing your total project costs!

PACKING & DELIVERY