Round Cooling Tower For Industrial Cooling

The distinguishing features of Latino's round type cooling tower are compact design with Honey comb type PVC fills, with varying flute sizes, to provide the maximum contacting surface area and heat transfer surface per unit volume.

- LATINO

- CHINA

- 3 MONTH

- 100 SET ONE MONTH

- Information

- Video

- Download

Round Cooling Tower For Industrial Cooling

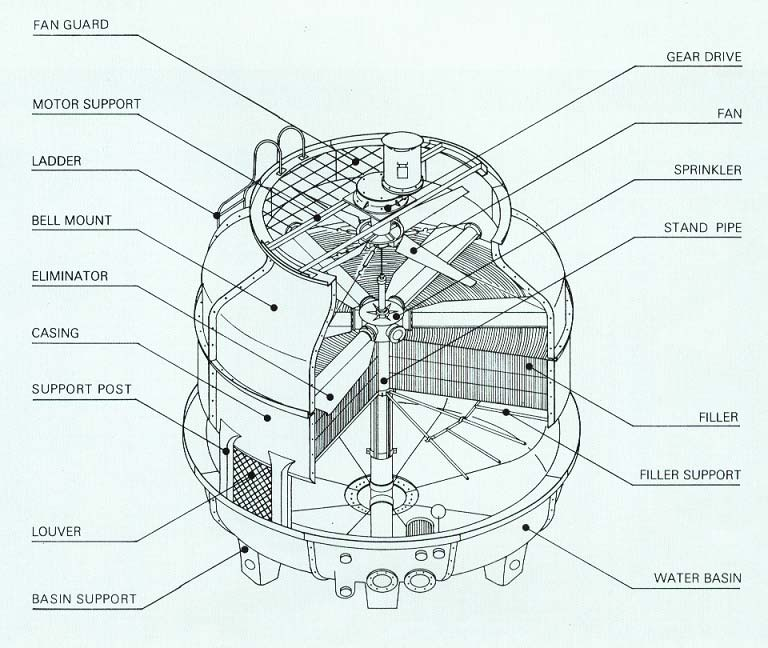

Latni's Round type cooling tower,Induced Draft Counter flow Cooling Tower is popularly known as bottle type cooling tower which are designed to cool industrial re-cycled process water from temperature of 50 degrees to temperature of 4 plus the prevailing Wet Bulb temperature of the region.

The cooling tower design incorporates hot water inlet at the bottom collection sump circulated vertically to the mechanical rotary sprinkler located above the cooling tower fill media. The inlet water pressure rotate the sprinkler, having extended arm pipes with orifices to disperse water uniformly over the PVC fill media.

The cooling tower fan directly coupled to the motor, during operations takes away the heat by induced draft mechanism. Air is drawn from the lower air in take area & is induced to travel through the cooling tower PVC fill media thus taking away the latent heat from the water passing through the round cooling tower fill media. Portion of water evaporated, removes the heat from the remaining water. The warm moist air is drawn through the fan deck is discharged to the atmosphere. Cold water, collected at the collection sump, is re-circulated to the source.

Industrial Round Type Cooling Tower is widely used in industries of Electric Power, Petroleum, Chemical Engineering, Chemical Fertilizer, Smelt, etc. Cooling water capacity ranges from 800 m3/h - 4000 m3/h. According to Customers' request, we also supply high temperature type, sewage type, and also designed to different shape to match with the customer's site location.

01- Technical Data Sheet

| Modle | water Flow | Motor | Dimensions | Pump Head | Weight |

| LRCM-DD | M3/H | KW | MM | mh20 | kg |

| 100 | 100 | 3.7 | 2005*2880*2850 | 3.6 | 850 |

| 125 | 125 | 3.7 | 2410*3180*2850 | 3.6 | 1030 |

| 150 | 150 | 3.7 | 2510*3380*2850 | 3.6 | 1120 |

| 175 | 175 | 3.7 | 2810*3380*2850 | 3.6 | 1200 |

| 200 | 200 | 5.5 | 2910*4180*2950 | 3.6 | 1540 |

| 225 | 225 | 5.5 | 2810*5480*3000 | 3.6 | 1860 |

| 250 | 250 | 7.5 | 2810*5480*3400 | 4.0 | 2000 |

| 300 | 300 | 7.5 | 3320*6080*3800 | 4.4 | 2300 |

| 350 | 350 | 7.5 | 3320*6080*4600 | 5.2 | 2420 |

| 100C2 | 200 | 3.7*2 | 4010*2880*2850 | 3.6 | 1600 |

| 125C2 | 250 | 3.7*2 | 4820*3180*2850 | 3.6 | 1960 |

| 150C2 | 300 | 3.7*2 | 5020*3380*2850 | 3.6 | 2140 |

| 175C2 | 350 | 3.7*2 | 5620*3380*2950 | 3.6 | 2300 |

| 200C2 | 400 | 5.5*2 | 5820*4180*2950 | 3.6 | 2980 |

| 225C2 | 450 | 5.5*2 | 5620*5480*3000 | 3.6 | 3580 |

| 250C2 | 500 | 7.5*2 | 5620*5480*3400 | 4.0 | 3840 |

| 300C2 | 600 | 7.5*2 | 6640*6080*3800 | 4.4 | 4420 |

| 350C2 | 700 | 7.5*2 | 6640*6080*4600 | 5.2 | 4640 |

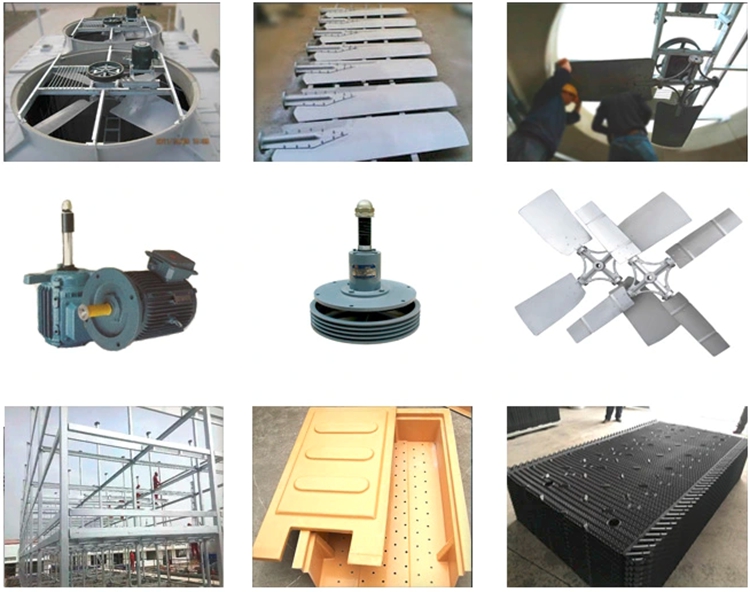

02- Cooling Tower Accessories

04 The Limited Value of Water Analysis

| Parameter | Make up water | Circulating Water | Parameter | Make Up Water | Circulating Water |

| PH Value | 6-8 | 6-8 | Chloric Acid IOD (CL-) ppm | 50 below | 200 below |

| Electric Conductivity | 200below | 500 below | Sulphuric ACID ION ppm | 50 below | 200 below |

| Total Hardness | 50below | 200 below | Silicic ACID ppm | 30 below | 50 below |

| Malkainity | 50 below | 100 below | Ferric (Fe) ppm | 0.3 below | 1.0 below |

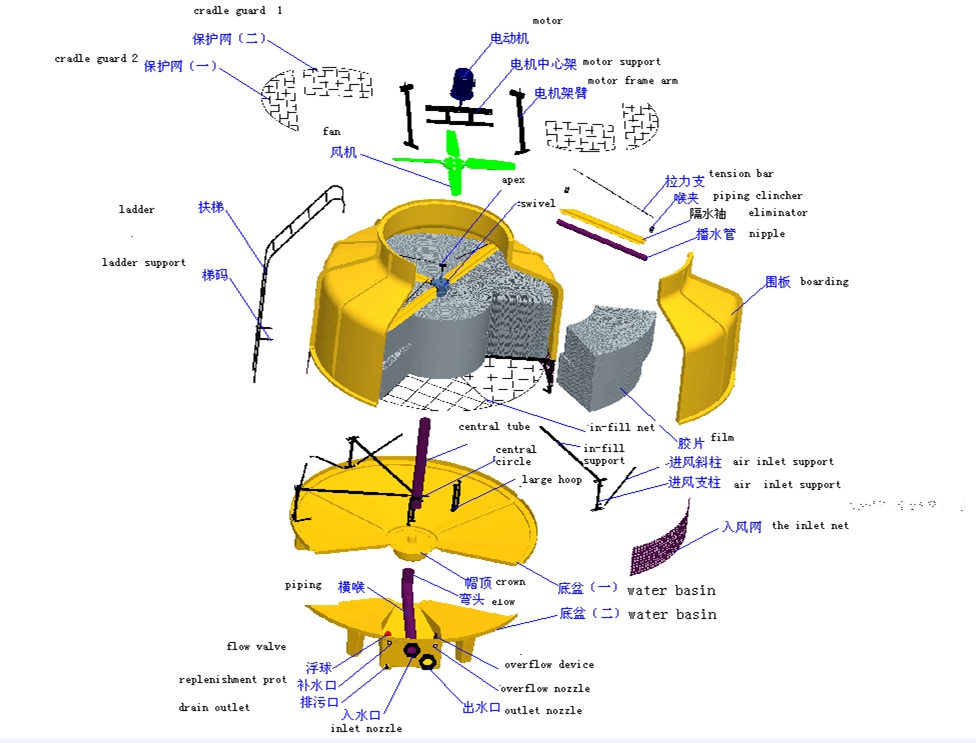

05-Instruction For The Cooling Tower Components

CASING AND WATER BASIN

Fiberglass reinforced polyester (FRP) is produced with the water-resistance resin and superior quality fiberglass mat. With good moisture, high gel,high strength, spray the gel-coat on FRP parts by machine and is thermal formed.

FAN & DRIVING SYSTEM

All the cooling tower fans with the adjustable pitch blades are applied to being balanced, it operates stably and quietly. The material for cooling tower fan are A.B.S, aluminum alloy for normal standard, F.R.P or stainless steel material available for all your options.Small capacity cooling tower adopts direct drive low noise fan. Bigger capacity fan equipped with Belt drive speed reducer or Gear box.

WATER DISTRIBUTION SYSTEM

Using high coefficient rotating sprinkler head which is made of plastic or aluminum alloy could reduce the pressure of friction loss, and the water can be distributed evenly to achieve the max thermal cooling performance.

COOLING TOWER FILL PACKING

Used high quality & improved performance PVC with good material, it is high cooling efficiency and anti-corrosive & UL V-0. The surface of cooling tower infill is corrugated to increase the filling pitch to make sure that infill is clog-free and overcome the problem of water quality. Special material for option if high entering water temperature.

COOLING TOWER FRAME

The cooling tower framework is made of hot dip galvanized steel (HDGS) or FRP, to makes the cooling tower in rust-free, durable and long service life.

06- Relevant Cooling Towers