Importance For Cooling Tower Parts

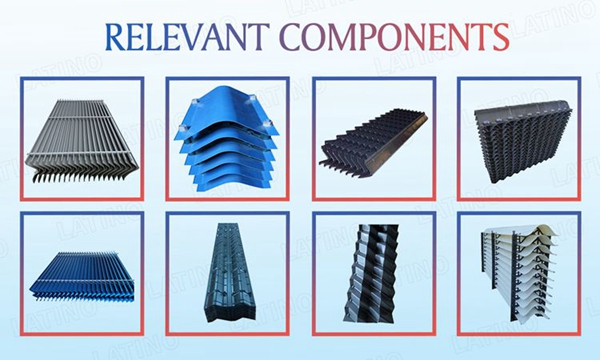

We ever introduced the function for the cooling tower fill. In the following, we will introduce the function for the cooling tower drift eliminator, cooling tower air inlet louver, and cooling tower nozzle.

One essential cooling tower part is the cooling tower drift eliminator. The purpose of this device is to capture the large water droplets in the cooling tower air stream and minimize the loss of process water.

Cooling tower eliminator redirects the moisture and water droplets towards another part of the system, preventing them from leaving the cooling tower. The air and water would afterward be separated and recycled for other operational purposes.

Apart from the necessity of process water loss prevention, the reason behind the elimination of these large water droplets is that they contain chemicals and minerals considered to be hazardous for the environment.

Cooling tower air inlet louvers are responsible for blocking the water from splashing out of the interior of the cooling tower preventing debris to enter it and also lowering the noise emission from the cooling tower.

In order to maintain good thermal efficiency, external sources of heating the tower shall be minimized. The cooling tower louvers also act as a shade to block the sunlight.

One of the cooling tower parts that is seen with crossflow cooling towers is the cooling tower nozzles. In the case of crossflow cooling towers, water is raised to the distribution basins and then cascaded down over the cooling tower fill through the cooling tower spray nozzles on the hot water basin floor.