News

Cooling Towers nozzle is an efficient, non-clogging nozzle designed specifically for all counterflow cooling tower applications. The design for this cooling tower nozzle provides excellent flow characteristics and a very uniform spray pattern, enhancing the cooling tower’s thermal performance. The unique color coding system allows for easy identification of the correct orifice size, from .75″ to 1.5″.

Noise level is an important techinical data in designing the cooling tower, it could affect the enduser's detailed requirments. So reducing the noise is an importance step for each of the cooling tower manufacture.

Cooling tower fill gluing process is an also very important for the cooling efficency.

Difference between the counter flow and cross flow cooling tower

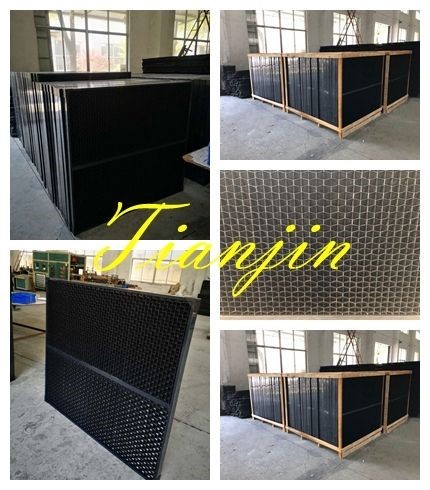

New cooling tower PP fill is widly used in the cooling tower industry.