- Home

- >

News

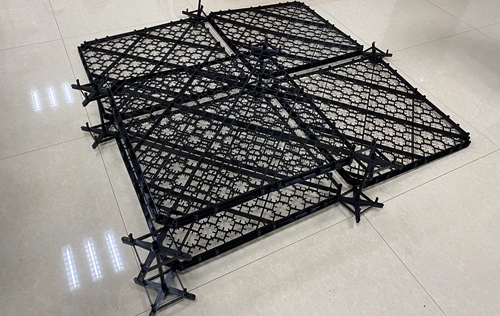

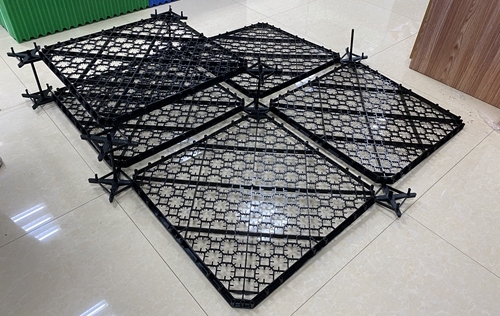

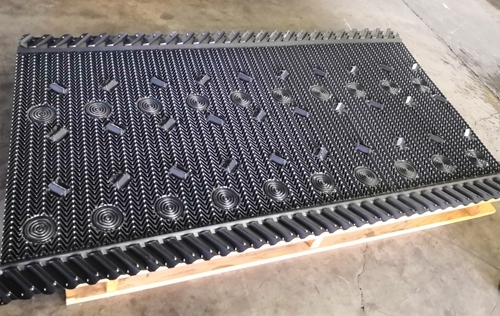

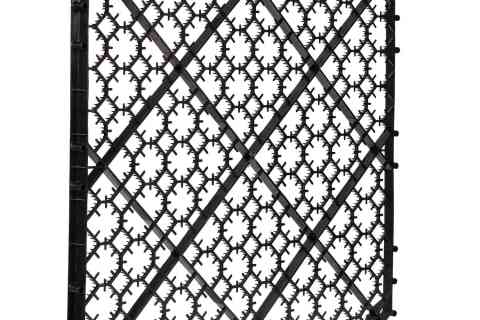

The grid fill is the result of an extensive optimization of the lath width, the blockage area ratio and the lath layout; The water droplets, splashing on a well drained lath, break in a large number of very small droplets, inducing large heat exchange surface. Blockage area ratio and lozenge layout is the optimized compromise between the pressure drop and the probability of large droplets to hit the laths. The laths height has been selected to transfer the load to the supporting spacers using minimum material quantity. It may be used as well in Counterflow as in Crossflow cooling towers, mechanical or natural draft. It is well adapted to any water quality, even without water treatment, when the fouling risk cannot be determined, in particular with seawater.

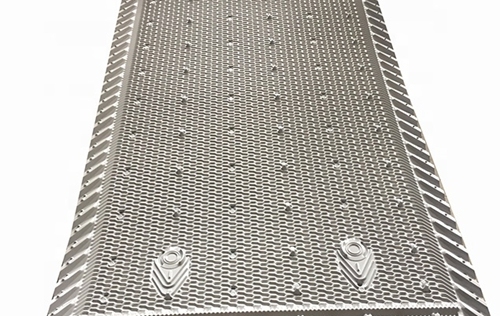

Marley MX75 is a hanging film type that is installed in a crossflow cooling tower. It achieves cooling by spreading water into a thin film over a large vertical surface thereby exposing the water to the maximum amount of air flow.

The grid fill is the result of an extensive optimization of the lath width, the blockage area ratio and the lath layout; The water droplets, splashing on a well drained lath, break in a large number of very small droplets, inducing large heat exchange surface. Blockage area ratio and lozenge layout is the optimized compromise between the pressure drop and the probability of large droplets to hit the laths. The laths height has been selected to transfer the load to the supporting spacers using minimum material quantity. It may be used as well in Counterflow as in Crossflow cooling towers, mechanical or natural draft. It is well adapted to any water quality, even without water treatment, when the fouling risk cannot be determined, in particular with seawater.

The grid fill is the result of an extensive optimization of the lath width, the blockage area ratio and the lath layout; The water droplets, splashing on a well drained lath, break in a large number of very small droplets, inducing large heat exchange surface. Blockage area ratio and lozenge layout is the optimized compromise between the pressure drop and the probability of large droplets to hit the laths. The laths height has been selected to transfer the load to the supporting spacers using minimum material quantity. It may be used as well in Counterflow as in Crossflow cooling towers, mechanical or natural draft. It is well adapted to any water quality, even without water treatment, when the fouling risk cannot be determined, in particular with seawater.

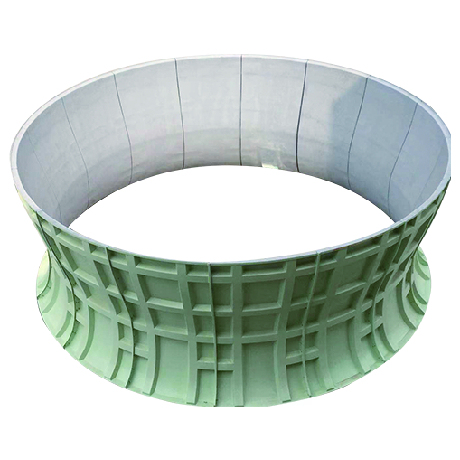

Cooling tower fan stack is an essential part of the cooling tower as well as a part of the propeller fan, mitigating pressure loss produced by high input air speed.