- Home

- >

News

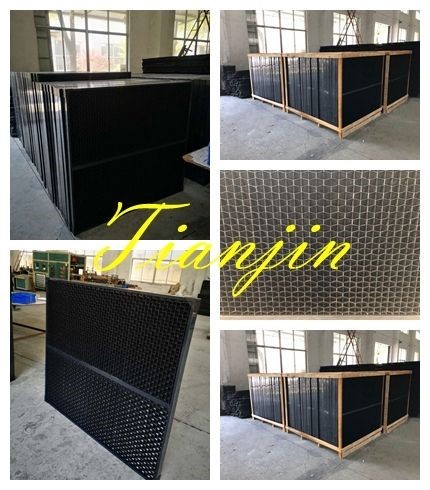

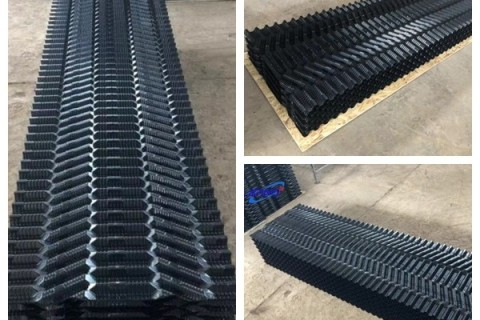

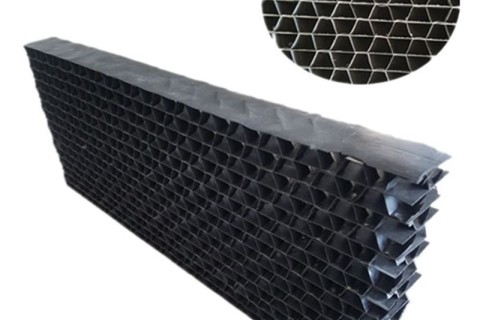

The grid fill is the result of an extensive optimization of the lath width, the blockage area ratio and the lath layout; The water droplets, splashing on a well drained lath, break in a large number of very small droplets, inducing large heat exchange surface. Blockage area ratio and lozenge layout is the optimized compromise between the pressure drop and the probability of large droplets to hit the laths. The laths height has been selected to transfer the load to the supporting spacers using minimum material quantity. It may be used as well in Counterflow as in Crossflow cooling towers, mechanical or natural draft. It is well adapted to any water quality, even without water treatment, when the fouling risk cannot be determined, in particular with seawater.

This BAC CF1200 New Type Non-Glued Counter Flow Cooling Tower Fills is used in: - TSS is less than 100 PPM with good microbiological control (less than 25PPM where microbiological control is poor); - Make-up from uncontaminated sources - Water treatment using oxidizing biocides & scale inhibitors - Low cycles of concentration - Minimal airborne dust - No potential for oil or grease contamination

The best selling product in Latino company this month: Cooling tower fill Width: 300 mm or 600 mm Sheet flute: 20 mm Thickness: 0.38 mm before forming or customized Length: customized

LATINO’s drift eliminators are specifically designed to achieve maximum drift removal efficiency in both crossflow and counterflow tower applications with various product options available to minimize pressure drop, drift loss, cost, or a combination of all three.

The counterflow sprayer is an injection molded ABS spiral target nozzle, assembled by two parts-the main body and orifice cap. It is used in the crossflow cooling tower. The uniform water distribution is the main factor for maintaining cooling tower efficiency. Latino's spiral target spray nozzles ensure hot water distribute uniformly to the fill blocks. This nozzle are high-temperature resistant and non-clogging designed.

This Cooling Tower Air Inlet Louver With Frame is used principally in situations of counterflow and crossflow applications: it is assembled by the preformed PVC sheets.