- Home

- >

News

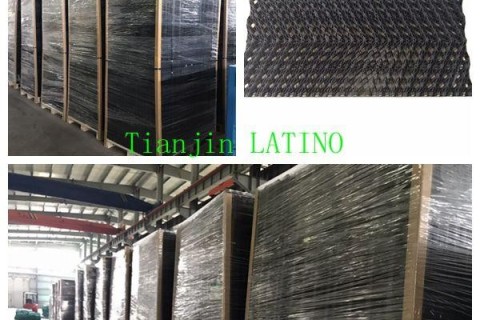

Very good new, Latino just received the feeback from our oversea customer.

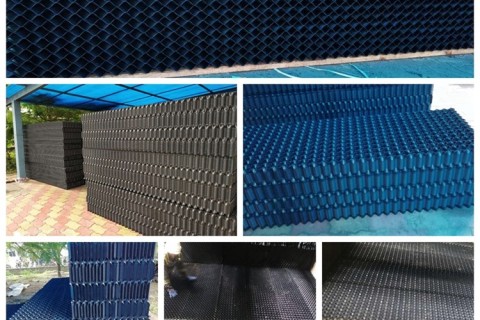

LATINO won the new order of cooling tower fill from Columbia on March.01,2019, the fill material is PVC and the type is LTN-9609 (CF1900), and PVC fill pitch is 19mm and 12mm, but the required thickness is 0.26mm before forming only. Thanks our cutomer for trust, we will deliver the goods on time.

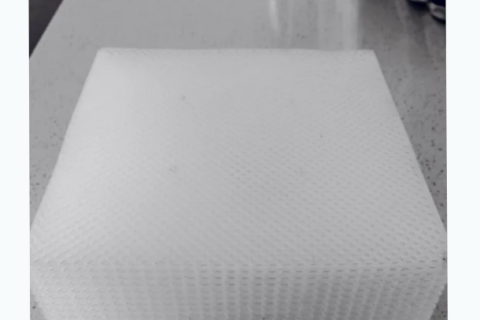

Marley MX75 is a hanging film type that is installed in a crossflow cooling tower. It achieves cooling by spreading water into a thin film over a large vertical surface thereby exposing the water to the maximum amount of air flow.

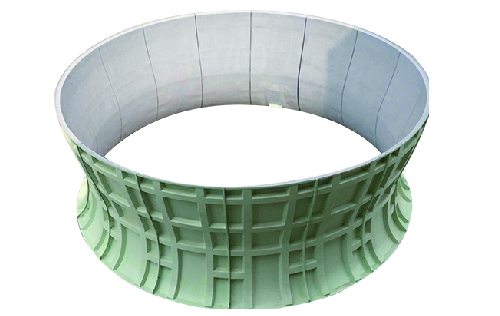

The fan stack is an essential part of the cooling tower as well as a part of the propeller fan, mitigating pressure loss produced by high input air speed.

Cooling Towers nozzle is an efficient, non-clogging nozzle designed specifically for all counterflow cooling tower applications. The design for this cooling tower nozzle provides excellent flow characteristics and a very uniform spray pattern, enhancing the cooling tower’s thermal performance. The unique color coding system allows for easy identification of the correct orifice size, from .75″ to 1.5″.

When certain materials are placed in the wastewater flow, removal efficiencies of oil increase due to impingement on their surface. Plastic media is particularly effective because of its oleophilic (oil attracting) characteristics. As fine oil droplets impinge upon or pass close to the plastic surface, they are attracted to it and adhere. Additional droplets continue to be attracted and coalesce or merge with previous droplets to produce much larger droplets. At a point, the droplets are large enough to break free and rise rapidly to the surface where they are skimmed or decanted. This coalescing action allows removal of smaller droplets than is possible with a straight gravity separator.

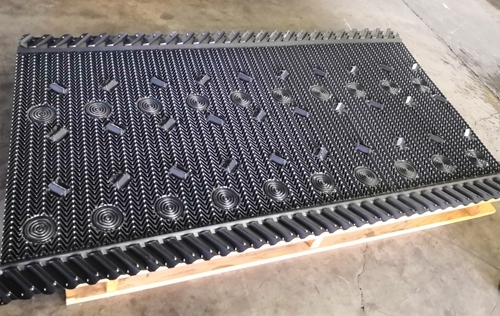

They will be used in 6 sets of cooling tower . This Cooling Tower Net Fills have been specially designed for medium to strongly polluted cooling water, the focus of the development being on a high stability as well as on easy and economical installation. Therefore these fills are built from mechanically joint grids and are easily cleaned. The cooling tower fill packings are high-performance fills which provide an optimized pressure drop. We offer a unique flexibility in measures for this fill type.

When certain materials are placed in the wastewater flow, removal efficiencies of oil increase due to impingement on their surface. Plastic media is particularly effective because of its oleophilic (oil attracting) characteristics. As fine oil droplets impinge upon or pass close to the plastic surface, they are attracted to it and adhere. Additional droplets continue to be attracted and coalesce or merge with previous droplets to produce much larger droplets. At a point, the droplets are large enough to break free and rise rapidly to the surface where they are skimmed or decanted. This coalescing action allows removal of smaller droplets than is possible with a straight gravity separator.

Cooling Towers nozzle is an efficient, non-clogging nozzle designed specifically for all counterflow cooling tower applications. The design for this cooling tower nozzle provides excellent flow characteristics and a very uniform spray pattern, enhancing the cooling tower’s thermal performance. The unique color coding system allows for easy identification of the correct orifice size, from .75″ to 1.5″.

Difference between the counter flow and cross flow cooling tower