- Home

- >

News

PVC Fill For Round Cooling Tower is heat-elimination in the cooling towers. It is a crucial component in the exchange of waterflow and gasflow process in the cooling tower. The PVC Fill For Round Cooling Tower is manufactured from PP or PVC sheets which are solvent-welded for maximum strength and resistance to organic and inorganic solvents, rot, fungus, UV, alkalis, acids and chemicals that are usually present in water. The PVC Fill For Round Cooling Tower has a unique design for counterflow round type cooling tower which is its most popular heat eliminating medium.

Some of orders recently which under the production : 1. SNCS cooling tower fill glue block 2. Drift Eliminator 3. Marley Type of Cooling tower Fill ( Width 1520mm ) Hot temperature and Covid-19 never stop us , LATINO can provide one stop service for the cooling tower and parts .

Second Batch-PP Net Fill, 2958.82 m3 , 10*40HQ dispatch yesterday, loading from morning to night , which will be 10 cells of Cooling Tower PP net Fill Size : 900* 450mm Pitch : 19mm Weight : 0.2 KG Material : PP Suitable : Dirty Water and High Temperature

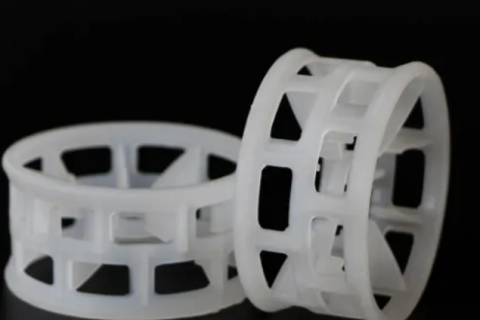

Grid Fills have been popular with the Cooling Tower Industry as a result of their efficiency of not only handling large quantities of water but also the overall tower efficiency. However in the case of heavily contaminated water, film type fills are susceptible to accumulating deposits and often make way for the use of splash type fills for effective water cooling. The forgiving nature of splash fills towards 'dirty' water and imperfect water distribution is offset by the need to have larger towers and thus higher capital costs as well as pumping heads.

They will be used in 6 sets of cooling tower . This Cooling Tower Net Fills have been specially designed for medium to strongly polluted cooling water, the focus of the development being on a high stability as well as on easy and economical installation. Therefore these fills are built from mechanically joint grids and are easily cleaned. The cooling tower fill packings are high-performance fills which provide an optimized pressure drop. We offer a unique flexibility in measures for this fill type.

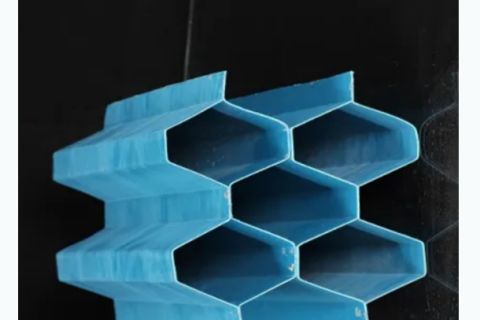

Drift eliminators are designed to capture large water droplets caught in the cooling tower air stream. The eliminators prevent the water droplets and mist from escaping the cooling tower. Eliminators do this by causing the droplets to change direction and lose velocity at impact on the blade walls and fall back into the tower. Efficient drift eliminators will keep drift losses to less than .001% of the re-circulating water flow rate.

It used in deposition and discharging sand. Recently, it is very popular in the drain aging project. With widely applicability, high efficiency, small proportion, it is very suitable not only in discharge, deposition of water from daily life and industry ,isolation of oil., but also in the project which is being constructing, re-construction of project.

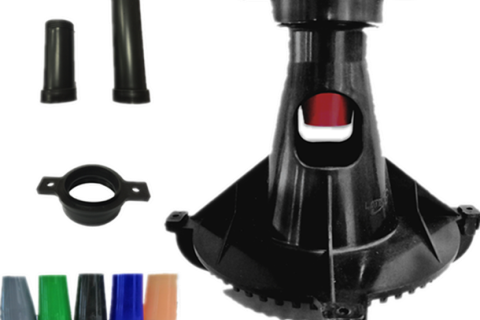

The cooling tower nozzle structure allows avoiding the formation of non-irrigated zones in the spray flame and achieving fine-dispersed sprinkling of water in the cooling tower, while the direct-flow shape of the cooling tower nozzle significantly reduces the likelihood of its being clogged with the admixtures in the water.

Liangchi Cooling Tower PVC Fill is widely used for the crossflow cooling towers.

We completed the cooling tower replacement and maintance in Ruiwan Hotel ,yrsterday they went to our warehouse assemble the cooling tower drift eliminator.

Cooling Towers nozzle is an efficient, non-clogging nozzle designed specifically for all counterflow cooling tower applications. The design for this cooling tower nozzle provides excellent flow characteristics and a very uniform spray pattern, enhancing the cooling tower’s thermal performance. The unique color coding system allows for easy identification of the correct orifice size, from .75″ to 1.5″.