- Home

- >

News

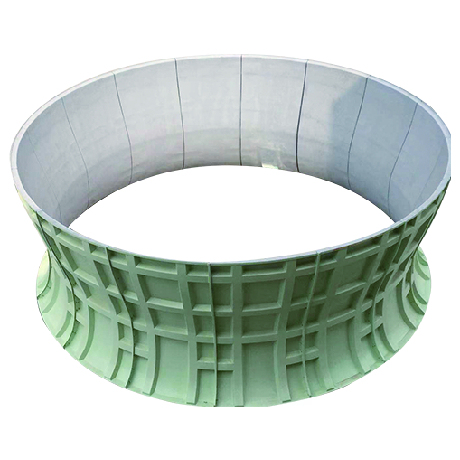

Cooling tower fan stack is an essential part of the cooling tower as well as a part of the propeller fan, mitigating pressure loss produced by high input air speed.

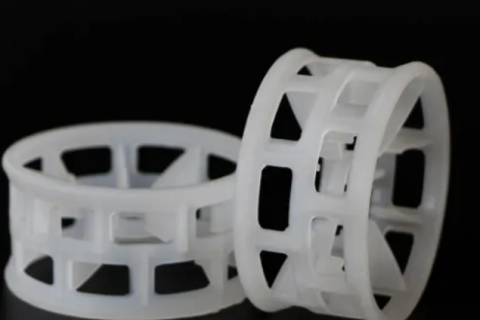

Plastic Random Packing added cone-shaped flanging at one edge. So it reduced the resistance when air pass through bed layer, and increased voidage. The height/diameter ratio of the plastic cascade ring packing is 0.5 which is only half that of the known plastic packing Pall Ring, Plastic Cascade Mini Ring can be installed in a tower that tends to orient in a more structured way such that its inner surface could be more efficient.

The fan stack is an essential part of the cooling tower as well as a part of the propeller fan, mitigating pressure loss produced by high input air speed. Fan stacks for cooling towers are made from layered laminated polyester, and they have a double-coat design. Their inner smooth surface allows for the fast removal of air. The outer surface provides high strength and resistance against climatic conditions and the operation of cooling towers. The shape of the classical cylindrical fan stack contributes to lower noise and vibration not only of the fan itself, but the whole cooling tower.

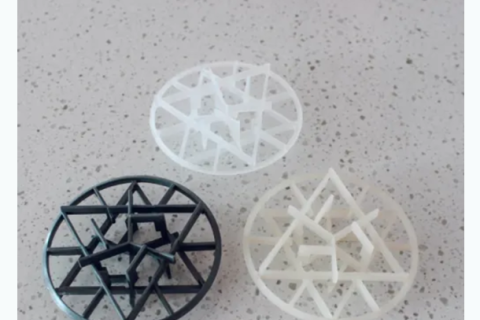

It offer superior separation efficiency and capacity in environmental application, such as scrubbing and stripping. Independent tests have proven Snowflake ring to be the most effective packing available for groundwater air stripping applications, yielding removal efficiency of 99 % or above. Its unique shape lowers pressure drop, which substantially reduces electrical energy consumption. In typical system designs , Snowflake ring can save more than 50% in energy costs than traditional i inch plastic saddles. In new installations, the pressure drop advantage of Snowflake Ring enables the designer to significantly reduce the size of towers and blowers.

Pall Ring is a proven design that provides higher capacity and lower pressure drop than trays and other random packings. By minimizing the number of contours and crevices that can cause liquid hold-up and potential entrainment, the pall ring geometry enables high gas and liquid transfer rates. The opened cylinder walls and inward bent protrusions of the Pall Ring allow greater capacity and lower pressure drop than standard cylindrical rings

As an international trade practitioner, i have sincerely explain to each of my customer our current status . We do not need to whitewash or conceal anything , because we have done our best to do a good job . We Latino was got the approve from government , and product safely and arrange the shipment for lots of orders

Latino finished the 50 m³ Mellaring for Indonesia with in 15 days.