- Home

- >

- News

- >

- Plastic Pall Ring

- >

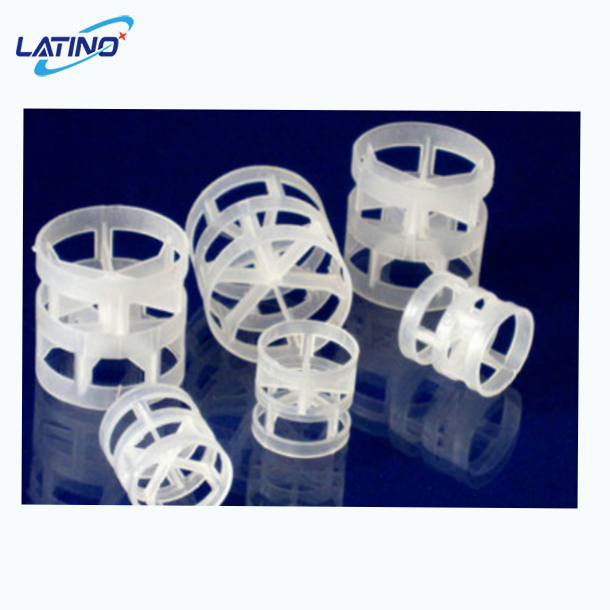

Plastic Pall Ring

2020-05-18 09:42

Pall Ring is a proven design that provides higher capacity and lower pressure drop than trays and other random packings.

By minimizing the number of contours and crevices that can cause liquid hold-up and potential entrainment, the pall ring geometry enables high gas and liquid transfer rates. The opened cylinder walls and inward bent protrusions of the Pall Ring allow greater capacity and lower pressure drop than standard cylindrical rings.

This open ring design also maintains an even distribution and resists wall-channeling tendencies. The interior and exterior contacting surfaces of the pall ring provide for an effective distribution of liquids and gasses and resist plugging, fouling and nesting. Pall rings are available from our stocked inventory in a wide range of materials.

Hold-up and Two-phase Contact

Promotes highly efficient two-phase contact and distribution;

A relatively high liquid hold-up promotes high absorption efficiencies, especially in cases where

Versatility

Mechanical Strength

Materials:

Plastic tower packings are made of heat resistant and chemical corrosion resistant plastics, including Polyethylene (PE), Polypropylene (PP), Reinforced Polypropylene(RPP), Polyvinyl Chloride(PVC), Chloridized Polyvinyl chloride(CPVC) and Polyvinylidene Fluoride (PVDF).

| D×H×δ mm | Specific area m2/m3 | Void rate % | Bulk number Pieces/m³ | Package density Kg/m³ | F factor m-1 |

| 16×16×1 | 188 | 0.91 | 170000 | 141 | 275 |

| 25×25×1.2 | 175 | 0.90 | 53500 | 82 | 239 |

| 38×38×1.4 | 115 | 0.89 | 15800 | 54 | 220 |

| 50×50×1.5 | 93 | 0.90 | 6500 | 56 | 127 |

| 76×76×2.6 | 73.2 | 0.92 | 1927 | 58 | 94 |

| 100×100×3.0 | 52.8 | 0.94 | 1000 | 50 | 82 |