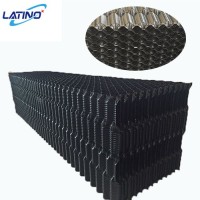

Cooling Tower Film Fill & Cooling Tower PVC Filler & Marley Cooling Tower Packing

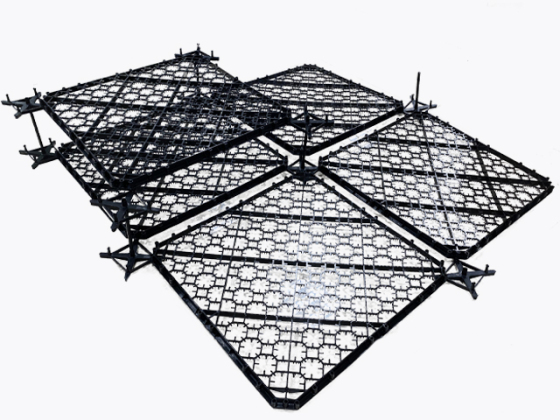

PVC square blocks Width 750mm crossflow cooling tower fill PVC Sheet Media

- Information

PVC square blocks Width 750mm crossflow cooling tower fill PVC Sheet Media

Cooling tower packing materials used xiao shucai, asbestos cement, cement grid, plastic, glass fiber reinforced plastics, ceramics and so on. The earliest cooling towers used only wood. Since wood is readily available, the fillers in cooling towers were almost always made of wood from the time they appeared until the 1960s. Mahogany is the most commonly used packing material for early cooling tower due to its anticorrosive property. The mahogany with long growing time is straight and firm in appearance, long service life and easy to use, so its price is higher. Later, there was a shortage of old mahogany and prices kept climbing.

PVC Fill for Cooling Tower power plant cooling tower

In the 1950s and 1960s, asbestos-cement sheet was widely used as the packing material for cooling towers. This material is highly resistant to corrosion. However, asbestos-cement was found to be harmful to the environment during processing and production, so the use of the material gradually declined, and some countries have banned it.

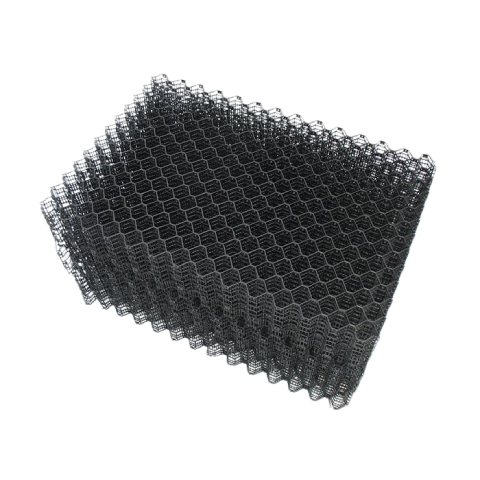

Pvc sheet spindle fill for spindle cooling tower

Around the 1970s, the emergence of plastic packing is a major innovation in the development of cooling towers. Plastic fillers were first used in the heating, ventilation and air conditioning industries, and later in the refining and power plant industries.

Sponsored Listing Contact Supplier Chat Now! PVC fills for Cooling tower(Crossflow)& EAC Cooling tower fills

This filler is characterized by good corrosion resistance and can be used for a long time. Plastic film packing is a great innovation in the history of cooling tower, because it increases the contact area between water and air. Therefore, it has better cooling capacity. However, under the working conditions of high temperature and humidity of cooling tower, aging and deformation of plastic filler will occur after working for about 3 years, affecting the cooling efficiency. In addition, winter ice will also have a greater impact on the plastic filler.

WholesaleHigh Efficiency round cooling tower pvc fill

In recent years, ceramic packing has been used in cooling tower of power plant. Not easy to take place geometric deformation, not brittle, and corrosion resistance, acid, alkali resistance. This kind of packing also has the characteristic is the antifreeze is very good, the tao research packing life is quite long, the service life design time is 30 years. The initial investment of this kind of filler is relatively large, the unit service for 30 years without replacement of the filler, operation and maintenance costs compared to other materials are relatively low.

Cooling Tower Film Fill & Cooling Tower PVC Filler & Marley Cooling Tower Packing,

China Supplier,Quality,Best Selling,OEM,Factory,Quotes,Brands,Buy,Cheap,China,Custom,Discount,Factory,Manufacturers,OEM,Price,Promotions,Purchase,Quality,Quotes,Sales,Supply,Wholesale,Produce