- Home

- >

- Products

- >

- Plastic Pall Ring

- >

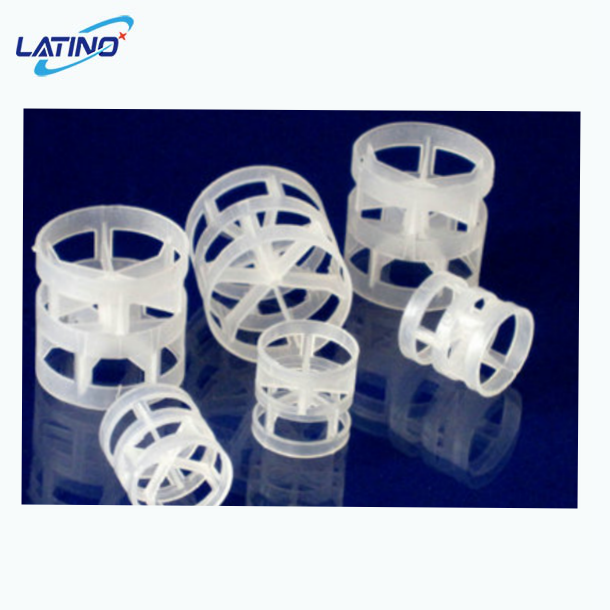

Plastic Pall Ring

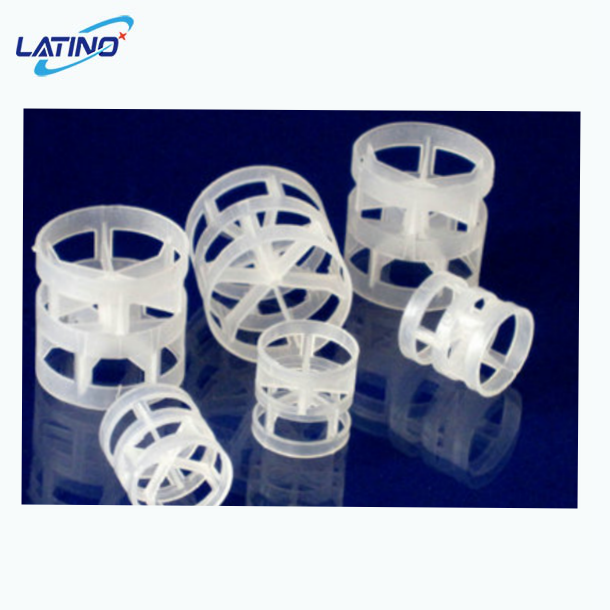

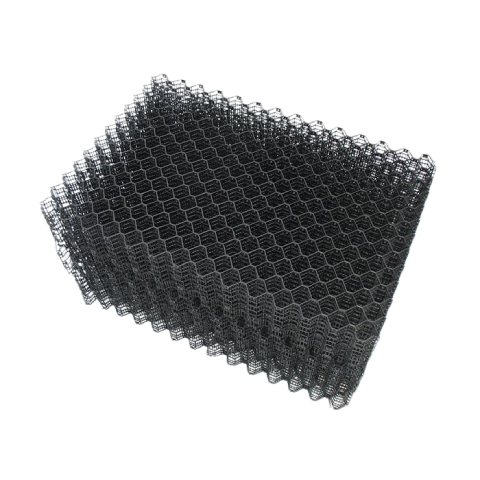

Pall Ring is a proven design that provides higher capacity and lower pressure drop than trays and other random packings.

By minimizing the number of contours and crevices that can cause liquid hold-up and potential entrainment, the pall ring geometry enables high gas and liquid transfer rates. The opened cylinder walls and inward bent protrusions of the Pall Ring allow greater capacity and lower pressure drop than standard cylindrical rings.

This open ring design also maintains an even distribution and resists wall-channeling tendencies. The interior and exterior contacting surfaces of the pall ring provide for an effective distribution of liquids and gasses and resist plugging, fouling and nesting. Pall rings are available from our stocked inventory in a wide range of materials.

- Latino

- China

- within 2 weeks

- 5000 m3/day

- Information

- Video

- Download

Plastic Pall Ring

Plastic Pall Ring

Pall Ring is a proven design that provides higher capacity and lower pressure drop than trays and other random packings.

By minimizing the number of contours and crevices that can cause liquid hold-up and potential entrainment, the pall ring geometry enables high gas and liquid transfer rates. The opened cylinder walls and inward bent protrusions of the Pall Ring allow greater capacity and lower pressure drop than standard cylindrical rings.

This open ring design also maintains an even distribution and resists wall-channeling tendencies. The interior and exterior contacting surfaces of the pall ring provide for an effective distribution of liquids and gasses and resist plugging, fouling and nesting. Pall rings are available from our stocked inventory in a wide range of materials.

Hold-up and Two-phase Contact

Promotes highly efficient two-phase contact and distribution;

A relatively high liquid hold-up promotes high absorption efficiencies, especially in cases where

Versatility

Mechanical Strength

Materials:

Plastic tower packings are made of heat resistant and chemical corrosion resistant plastics, including Polyethylene (PE), Polypropylene (PP), Reinforced Polypropylene(RPP), Polyvinyl Chloride(PVC), Chloridized Polyvinyl chloride(CPVC) and Polyvinylidene Fluoride (PVDF).

| D×H×δ mm | Specific area m2/m3 | Void rate % | Bulk number Pieces/m³ | Package density Kg/m³ | F factor m-1 |

| 16×16×1 | 188 | 0.91 | 170000 | 141 | 275 |

| 25×25×1.2 | 175 | 0.90 | 53500 | 82 | 239 |

| 38×38×1.4 | 115 | 0.89 | 15800 | 54 | 220 |

| 50×50×1.5 | 93 | 0.90 | 6500 | 56 | 127 |

| 76×76×2.6 | 73.2 | 0.92 | 1927 | 58 | 94 |

| 100×100×3.0 | 52.8 | 0.94 | 1000 | 50 | 82 |

Tianjin LATINO Environmental Technology Co., Ltd. are on the base of high quality, good service, we win good reputation in the industry. We help our customers better to get cooling tower products from China.We specializes in manufacturing various cooling tower and parts. Our company's cooling tower products is being used widely around the world. Our business involve in Italy, Germany, Australia, UK, Indonesia, Thailand, Belgium, France, Poland, India, Malaysia, Singapore and New Zealand, etc..

Latino has a high quality team of talents. Team members are young and energetic, with a sense of innovation and the courage to meet the challenge.Team members develop and practice new e-marketing mode, follow consumer demand, provide customers with high quality products and services.

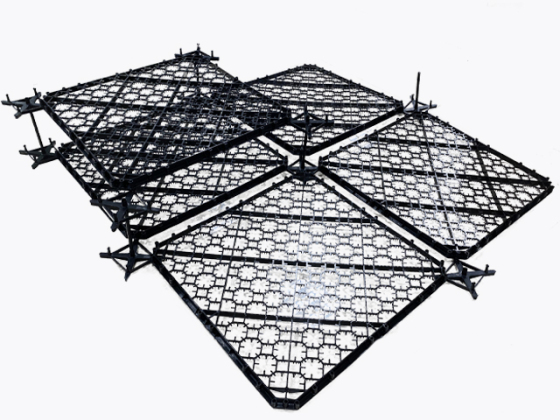

LATINO has an experienced team in quality and project implement to support the purchasing activities of overseas customers;The company's main products are cooling tower parts, such as Film Fill, drift eliminator and spray system, UPVC distribution pipes, FPR winding splash pipe, FRP profile parts,FRP gratings, Fan stack, band & clamp, etc.; Our product are approved by CTI and we have our own patent .

Our factory has the largest capacity and have been working with the recognized brands of cooling tower in around the world, our team have rich experience in oversea projects.we were your colleague, knowing your care, your culture and your requirements.So we make it easy for you to purchase high quality and good value internal plastic parts of cooling tower in China.

Our fill has been verified by actual operation for more than ten years. It is very reliable and efficient. You can rely on us to deliver a successful project while reducing your total project costs!