Latino New Cooling Tower Case

Cooling tower is a heat removal device that uses water to transfer process waste heat into the atmosphere. All the cooling towers operate on the principle of removing the heat from flowing water by evaporating a small portion of water that is recirculated through the unit. The mixing of warm water and cooler air releases latent heat of vaporization, causing the water to cool. If you are ever looking down from a high-rise building, you might notice square units with fans on top of them on the buildings below. Those are cooling towers.

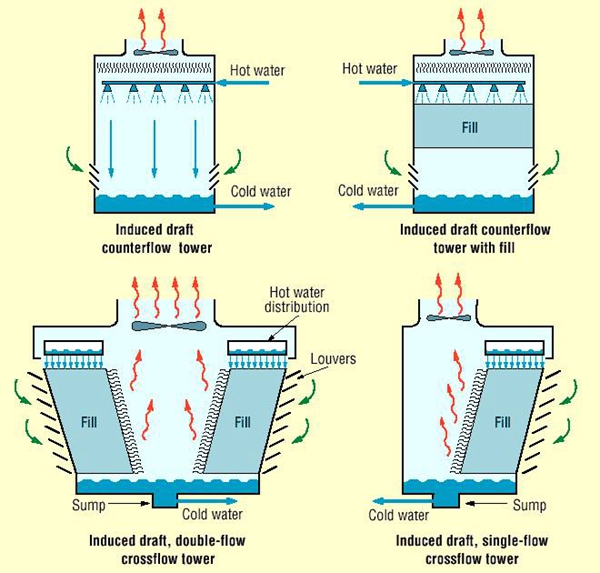

Most packaged cooling towers use cooling tower fans to force or draw air through the cooling tower. Countercurrent-induced draft cooling towers are the most prevalent in the process industries, capable of cooling water within just over 1 °C (2 °F) of the wet-bulb air temperature.

Induced draft cooling towers have fans at the discharge that pull the air through. This produces low entering and high exit air velocities, reducing the possibility of recirculation, in which discharged air flows back into the air intake. Location of the fan in the warm air stream provides excellent protection against icing of the mechanical components. Cooling towers range from 3 to 160,000 m3/h (15 to 700,000 gpm).

Forced draft ccooling towers have fans at the air intake to the tower. This creates high entering and low exiting air velocities. The low exit velocity is more prone to recirculation. Forced draft designs typically require more motor power than equivalent induced draft cooling towers because they are usually equipped with centrifugal blower type fans. The primary benefit is that high pressure drops through the cooling tower are possible, enabling a more compact design and indoor installations.

Counterflow cooling towers are similar to packed bed strippers. The air flows up through the packed cooling tower fill material while the water flows down, countercurrently. Circulated water is distributed across the cooling tower fill through cooling tower spray nozzles. Most new cooling towers are of the counterflow design, with low-clog film type cooling tower fill material.

Latino just finished one set FRP counterflow cooling tower with two cells in oversea projects. Thanks to the professional local installation teams, we finished the installation within one month, and now the cooling tower were pre-commission yesterday, and the result were completely satisfy the original designed cooling effiency.