- Home

- >

- News

- >

- Industry News

- >

News

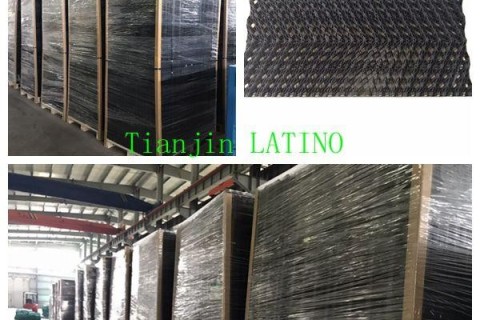

They will be used in 6 sets of cooling tower . This Cooling Tower Net Fills have been specially designed for medium to strongly polluted cooling water, the focus of the development being on a high stability as well as on easy and economical installation. Therefore these fills are built from mechanically joint grids and are easily cleaned. The cooling tower fill packings are high-performance fills which provide an optimized pressure drop. We offer a unique flexibility in measures for this fill type.

They will be used in 6 sets of cooling tower . This Cooling Tower Net Fills have been specially designed for medium to strongly polluted cooling water, the focus of the development being on a high stability as well as on easy and economical installation. Therefore these fills are built from mechanically joint grids and are easily cleaned. The cooling tower fill packings are high-performance fills which provide an optimized pressure drop. We offer a unique flexibility in measures for this fill type.

Splash grid fill for cooling tower Available size: 955 (length)* 705 (width) mm 705 (length)* 705 (width) mm 705 (length)* 255 (width) mm All the accessories can also be provided.

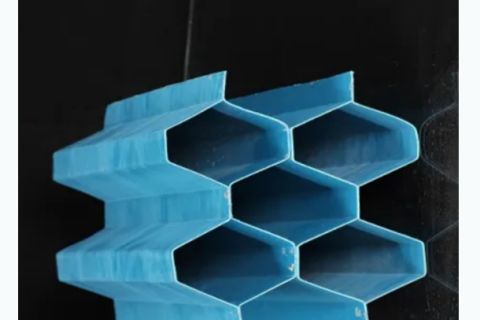

It used in deposition and discharging sand. Recently, it is very popular in the drain aging project. With widely applicability, high efficiency, small proportion, it is very suitable not only in discharge, deposition of water from daily life and industry ,isolation of oil., but also in the project which is being constructing, re-construction of project.

When certain materials are placed in the wastewater flow, removal efficiencies of oil increase due to impingement on their surface. Plastic media is particularly effective because of its oleophilic (oil attracting) characteristics. As fine oil droplets impinge upon or pass close to the plastic surface, they are attracted to it and adhere. Additional droplets continue to be attracted and coalesce or merge with previous droplets to produce much larger droplets. At a point, the droplets are large enough to break free and rise rapidly to the surface where they are skimmed or decanted. This coalescing action allows removal of smaller droplets than is possible with a straight gravity separator.

Plastic Random Packing added cone-shaped flanging at one edge. So it reduced the resistance when air pass through bed layer, and increased voidage. The height/diameter ratio of the plastic cascade ring packing is 0.5 which is only half that of the known plastic packing Pall Ring, Plastic Cascade Mini Ring can be installed in a tower that tends to orient in a more structured way such that its inner surface could be more efficient.

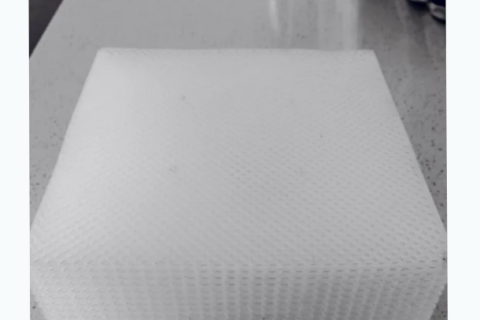

LATINO’s drift eliminators are specifically designed to achieve maximum drift removal efficiency in both crossflow and counterflow tower applications with various product options available to minimize pressure drop, drift loss, cost, or a combination of all three.

The fan stack is an essential part of the cooling tower as well as a part of the propeller fan, mitigating pressure loss produced by high input air speed. Fan stacks for cooling towers are made from layered laminated polyester, and they have a double-coat design. Their inner smooth surface allows for the fast removal of air. The outer surface provides high strength and resistance against climatic conditions and the operation of cooling towers. The shape of the classical cylindrical fan stack contributes to lower noise and vibration not only of the fan itself, but the whole cooling tower.

The ABS spray nozzle is also called the hollow cone spray nozzle is available in two diameters and it's used on wood, steel, and fiberglass cooling towers, Natrual draft cooling tower and induced draft cooling tower. The cooling tower nozzle structure allows avoiding the formation of non-irrigated zones in the spray flame and achieving fine-dispersed sprinkling of water in the cooling tower, while the direct-flow shape of the cooling tower nozzle significantly reduces the likelihood of its being clogged with the admixtures in the water.

The fan stack is an essential part of the cooling tower as well as a part of the propeller fan, mitigating pressure loss produced by high input air speed. Fan stacks for cooling towers are made from layered laminated polyester, and they have a double-coat design. Their inner smooth surface allows for the fast removal of air. The outer surface provides high strength and resistance against climatic conditions and the operation of cooling towers. The shape of the classical cylindrical fan stack contributes to lower noise and vibration not only of the fan itself, but the whole cooling tower.