- Home

- >

- News

- >

- Industry News

- >

News

Grid Fills have been popular with the Cooling Tower Industry as a result of their efficiency of not only handling large quantities of water but also the overall tower efficiency. However in the case of heavily contaminated water, film type fills are susceptible to accumulating deposits and often make way for the use of splash type fills for effective water cooling. The forgiving nature of splash fills towards 'dirty' water and imperfect water distribution is offset by the need to have larger towers and thus higher capital costs as well as pumping heads.

The Cooling Tower Nozzle will be shipment in this Sunday,about 15days arrive in our customer company. This Crossflow Spiral ABS Nozzle For Cooling Tower is available in 13mm, 17mm, 26mm and 19mm This amount of flexibility allows for a wide raCrossflow Spiral ABS Nozzle For Cooling Tower nge of adjustment in water flow rates and basin water levels.

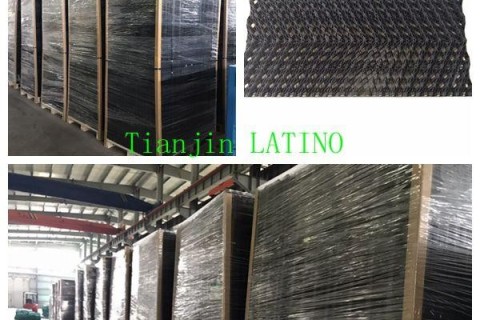

Here I would like to share the cooling tower fill information with you: Just Now 48 boxes of SNCS fill were delivered to Shanghai port from our factory. Size: 1830*1220 mm and 1830*610 Thickness: 0.45 mm before forming

This cunterflow cooling tower fill is used in: - TSS is less than 100 PPM with good microbiological control (less than 25PPM where microbiological control is poor); - Make-up from uncontaminated sources - Water treatment using oxidizing biocides & scale inhibitors - Low cycles of concentration - Minimal airborne dust - No potential for oil or grease contamination

Same Tune, share view with Canton Fair. Welcome to our Online Canton Fair , please Scan the QR code. From June 15th to June 24thwe are waiting for you online.

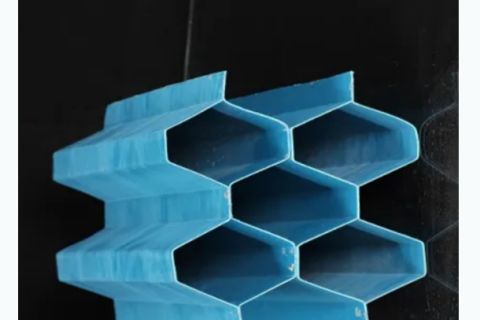

They will be used in 6 sets of cooling tower . This Cooling Tower Net Fills have been specially designed for medium to strongly polluted cooling water, the focus of the development being on a high stability as well as on easy and economical installation. Therefore these fills are built from mechanically joint grids and are easily cleaned. The cooling tower fill packings are high-performance fills which provide an optimized pressure drop. We offer a unique flexibility in measures for this fill type.

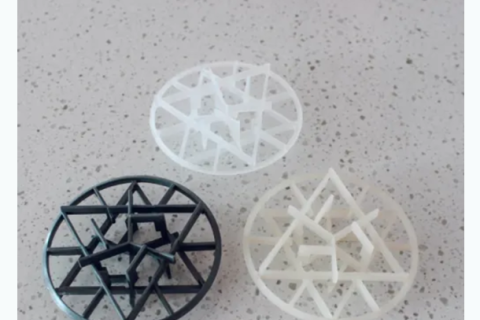

It offer superior separation efficiency and capacity in environmental application, such as scrubbing and stripping. Independent tests have proven Snowflake ring to be the most effective packing available for groundwater air stripping applications, yielding removal efficiency of 99 % or above. Its unique shape lowers pressure drop, which substantially reduces electrical energy consumption. In typical system designs , Snowflake ring can save more than 50% in energy costs than traditional i inch plastic saddles. In new installations, the pressure drop advantage of Snowflake Ring enables the designer to significantly reduce the size of towers and blowers.

Drift eliminators are designed to capture large water droplets caught in the cooling tower air stream. The eliminators prevent the water droplets and mist from escaping the cooling tower. Eliminators do this by causing the droplets to change direction and lose velocity at impact on the blade walls and fall back into the tower. Efficient drift eliminators will keep drift losses to less than .001% of the re-circulating water flow rate.

It used in deposition and discharging sand. Recently, it is very popular in the drain aging project. With widely applicability, high efficiency, small proportion, it is very suitable not only in discharge, deposition of water from daily life and industry ,isolation of oil., but also in the project which is being constructing, re-construction of project.

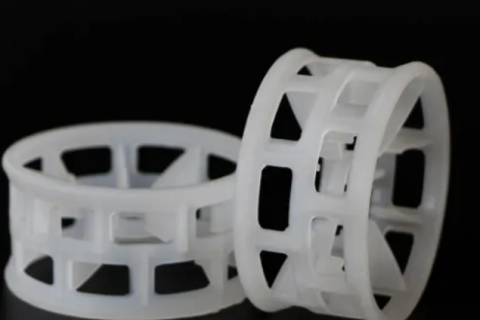

Pall Ring is a proven design that provides higher capacity and lower pressure drop than trays and other random packings. By minimizing the number of contours and crevices that can cause liquid hold-up and potential entrainment, the pall ring geometry enables high gas and liquid transfer rates. The opened cylinder walls and inward bent protrusions of the Pall Ring allow greater capacity and lower pressure drop than standard cylindrical rings

The oil water separator is made in oleophilic polypropylene, with all rounded surfaces at a 90 degree angle vs. the direction of water flow and many slender rods pointing down towards the sludge compartment, offers a solution to the maintenance problems that, until now, have been aOil in water coalescing mediaccepted practice in the oil water separation industry. It was recognized a revolutionary coalescing media which can separate oil from water containing suspended particulate.Large surface area makes it very suitable as a biological support media.Each layer' s densely pore distribution and layers interlocking will promote small oil free molecular rapidly contacts with lipophili surface, finally form a big oil droplet.it will large shorten oil & water separating time.The vertical rod' s distribution on the bottom of each layer will speed up oil & water fall off quickly and not create any blocking.Above special design make filter block becomes a kind of ideal carrier used in odor-control scrubbers bottom of each layer will speed up oil & water fall off quickly and not create any blocking.Above special design make filter block becomes a kind of ideal carrier used in odor-control scrubbers & oil-water separators.