- Home

- >

News

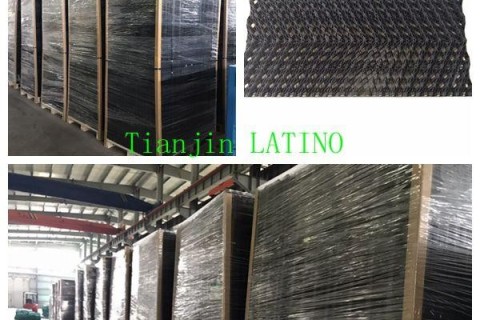

Packaging Improvement : In order to reduce the impact of high temperature in the container during the shipment , we use special heat insulation film to wrap the outside of the cooling tower fill, we reinforce the pallets in the container to prevent the pallets shaking in the container. We are very careful to deal with each customer's order, and improving the quality and service.

PVC Fill For Round Cooling Tower is heat-elimination in the cooling towers. It is a crucial component in the exchange of waterflow and gasflow process in the cooling tower. The PVC Fill For Round Cooling Tower is manufactured from PP or PVC sheets which are solvent-welded for maximum strength and resistance to organic and inorganic solvents, rot, fungus, UV, alkalis, acids and chemicals that are usually present in water. The PVC Fill For Round Cooling Tower has a unique design for counterflow round type cooling tower which is its most popular heat eliminating medium.

Splash grid fill for cooling tower Available size: 955 (length)* 705 (width) mm 705 (length)* 705 (width) mm 705 (length)* 255 (width) mm All the accessories can also be provided.

Some of orders recently which under the production : 1. SNCS cooling tower fill glue block 2. Drift Eliminator 3. Marley Type of Cooling tower Fill ( Width 1520mm ) Hot temperature and Covid-19 never stop us , LATINO can provide one stop service for the cooling tower and parts .

Second Batch-PP Net Fill, 2958.82 m3 , 10*40HQ dispatch yesterday, loading from morning to night , which will be 10 cells of Cooling Tower PP net Fill Size : 900* 450mm Pitch : 19mm Weight : 0.2 KG Material : PP Suitable : Dirty Water and High Temperature

Good news! Maintenance project for eight cooling towers has been completed yesterday in China, we changed the cooling tower fill (CF1900 fill) and drift eliminator which you can see from the picture.

The Cooling Tower Nozzle will be shipment in this Sunday,about 15days arrive in our customer company. This Crossflow Spiral ABS Nozzle For Cooling Tower is available in 13mm, 17mm, 26mm and 19mm This amount of flexibility allows for a wide raCrossflow Spiral ABS Nozzle For Cooling Tower nge of adjustment in water flow rates and basin water levels.

Here I would like to share the cooling tower fill information with you: Just Now 48 boxes of SNCS fill were delivered to Shanghai port from our factory. Size: 1830*1220 mm and 1830*610 Thickness: 0.45 mm before forming

This cunterflow cooling tower fill is used in: - TSS is less than 100 PPM with good microbiological control (less than 25PPM where microbiological control is poor); - Make-up from uncontaminated sources - Water treatment using oxidizing biocides & scale inhibitors - Low cycles of concentration - Minimal airborne dust - No potential for oil or grease contamination

Same Tune, share view with Canton Fair. Welcome to our Online Canton Fair , please Scan the QR code. From June 15th to June 24thwe are waiting for you online.

They will be used in 6 sets of cooling tower . This Cooling Tower Net Fills have been specially designed for medium to strongly polluted cooling water, the focus of the development being on a high stability as well as on easy and economical installation. Therefore these fills are built from mechanically joint grids and are easily cleaned. The cooling tower fill packings are high-performance fills which provide an optimized pressure drop. We offer a unique flexibility in measures for this fill type.

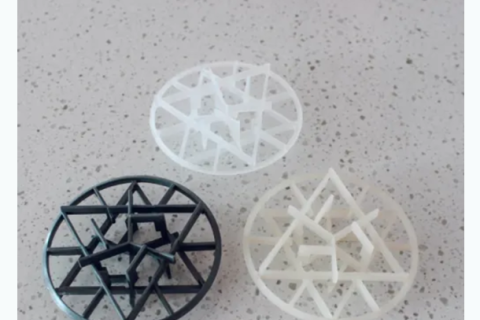

It offer superior separation efficiency and capacity in environmental application, such as scrubbing and stripping. Independent tests have proven Snowflake ring to be the most effective packing available for groundwater air stripping applications, yielding removal efficiency of 99 % or above. Its unique shape lowers pressure drop, which substantially reduces electrical energy consumption. In typical system designs , Snowflake ring can save more than 50% in energy costs than traditional i inch plastic saddles. In new installations, the pressure drop advantage of Snowflake Ring enables the designer to significantly reduce the size of towers and blowers.