- Home

- >

News

Cooling Towers nozzle is an efficient, non-clogging nozzle designed specifically for all counterflow cooling tower applications. The design for this cooling tower nozzle provides excellent flow characteristics and a very uniform spray pattern, enhancing the cooling tower’s thermal performance. The unique color coding system allows for easy identification of the correct orifice size, from .75″ to 1.5″.

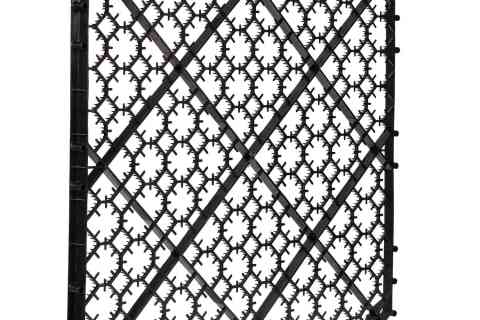

The grid fill is the result of an extensive optimization of the lath width, the blockage area ratio and the lath layout; The water droplets, splashing on a well drained lath, break in a large number of very small droplets, inducing large heat exchange surface. Blockage area ratio and lozenge layout is the optimized compromise between the pressure drop and the probability of large droplets to hit the laths. The laths height has been selected to transfer the load to the supporting spacers using minimum material quantity. It may be used as well in Counterflow as in Crossflow cooling towers, mechanical or natural draft. It is well adapted to any water quality, even without water treatment, when the fouling risk cannot be determined, in particular with seawater.

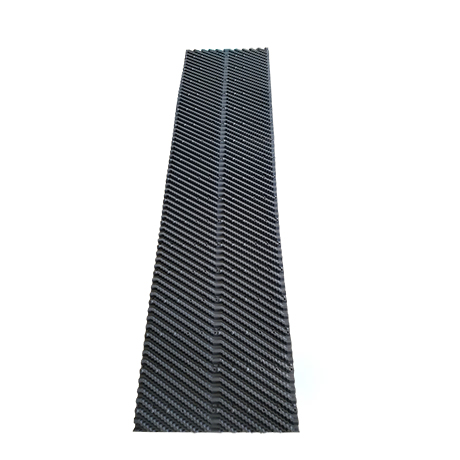

Cooling tower fill is one of the most important components for exchange of gas and water in cooling tower. The cooling tower fill is made by the cooling tower PVC sheet. The heat and resistance characteristic of the cooling tower fill are the main factors influencing the cooling efficiency. Moreover the quality of the material will influence the fill's lifetime. LATINO choose the high quality fill for the cooling tower. LATINO'S cooling tower fill is with the advantages of good chemical stability, resistant acid, alkali and organic solvent corrosion, high cooling efficiency, small ventilation resistance, strong hydrophilicity, large contact area etc.

The best selling product in Latino company this month: Cooling tower fill Width: 300 mm or 600 mm Sheet flute: 20 mm Thickness: 0.38 mm before forming or customized Length: customized

Cooling tower fill gluing process is an also very important for the cooling efficency.

Noise level is an important techinical data in designing the cooling tower, it could affect the enduser's detailed requirments. So reducing the noise is an importance step for each of the cooling tower manufacture.

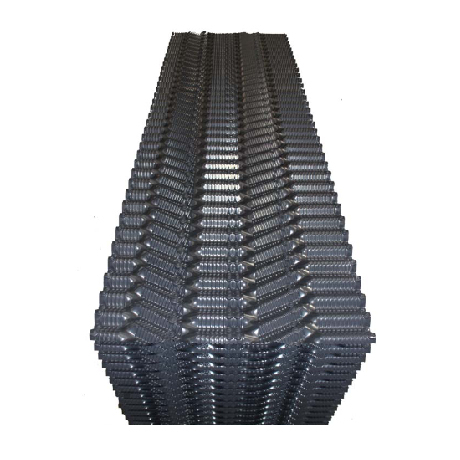

New cooling tower PP fill is widly used in the cooling tower industry.