News

New cooling tower PP fill is widly used in the cooling tower industry.

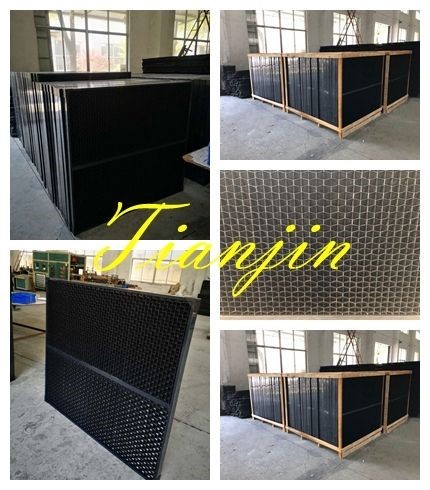

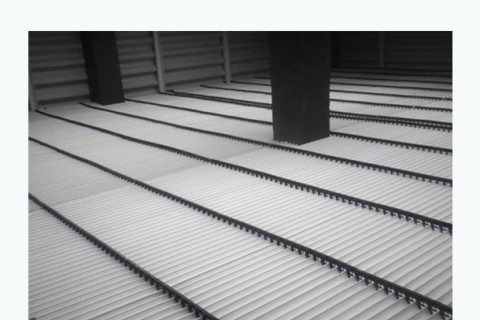

The grid fill is the result of an extensive optimization of the lath width, the blockage area ratio and the lath layout; The water droplets, splashing on a well drained lath, break in a large number of very small droplets, inducing large heat exchange surface. Blockage area ratio and lozenge layout is the optimized compromise between the pressure drop and the probability of large droplets to hit the laths. The laths height has been selected to transfer the load to the supporting spacers using minimum material quantity. It may be used as well in Counterflow as in Crossflow cooling towers, mechanical or natural draft. It is well adapted to any water quality, even without water treatment, when the fouling risk cannot be determined, in particular with seawater.

Spiral Target Cross Flow Cooling Tower Spray Nozzle is made by PP material, and assembled by several parts. It is widely used for the counterflow cooling tower. Spiral Target Cross Flow Cooling Tower Spray Nozzle help ensure a uniformly delivery of water over the cooling tower fill. Uniform water distribution at the top of the cooling tower fill is essential to achieve proper wetting of the entire cooling tower infill surface.

The fan stack is an essential part of the cooling tower as well as a part of the propeller fan, mitigating pressure loss produced by high input air speed. Fan stacks for cooling towers are made from layered laminated polyester, and they have a double-coat design. Their inner smooth surface allows for the fast removal of air. The outer surface provides high strength and resistance against climatic conditions and the operation of cooling towers. The shape of the classical cylindrical fan stack contributes to lower noise and vibration not only of the fan itself, but the whole cooling tower.

When certain materials are placed in the wastewater flow, removal efficiencies of oil increase due to impingement on their surface. Plastic media is particularly effective because of its oleophilic (oil attracting) characteristics. As fine oil droplets impinge upon or pass close to the plastic surface, they are attracted to it and adhere. Additional droplets continue to be attracted and coalesce or merge with previous droplets to produce much larger droplets. At a point, the droplets are large enough to break free and rise rapidly to the surface where they are skimmed or decanted. This coalescing action allows removal of smaller droplets than is possible with a straight gravity separator.

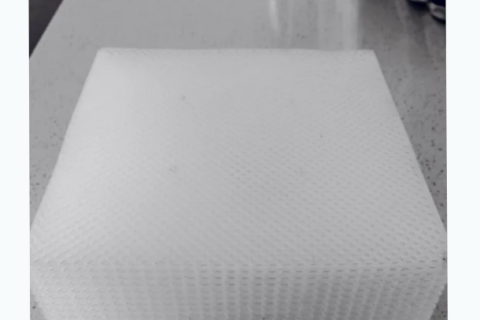

This BAC CF1200 New Type Non-Glued Counter Flow Cooling Tower Fills is used in: - TSS is less than 100 PPM with good microbiological control (less than 25PPM where microbiological control is poor); - Make-up from uncontaminated sources - Water treatment using oxidizing biocides & scale inhibitors - Low cycles of concentration - Minimal airborne dust - No potential for oil or grease contamination

The cooling tower drift eliminator/ air inlet louver is very important in the cooling tower.

Cooling tower nozzles can either be fixed in place while spraying in a round or square pattern, or they can be part of a rotating assembly as found in some circular crossflow cooling towers.