News

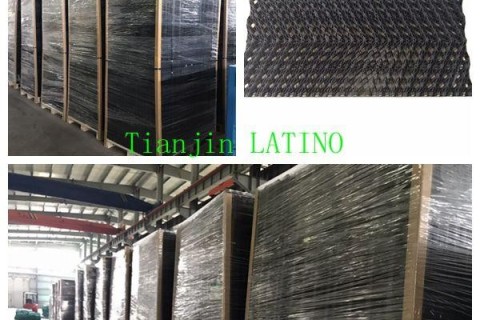

Cooling Tower PP Net Fill

New cooling tower PP fill is widly used in the cooling tower industry.

2021/04/08

READ MORE

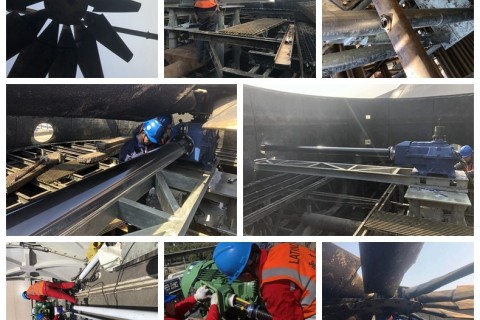

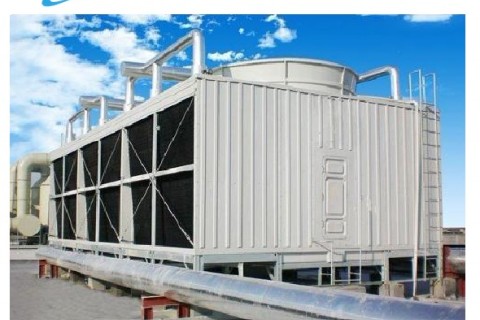

Cooling Tower Wet Net Fills For Dirty Water

They will be used in 6 sets of cooling tower . This Cooling Tower Net Fills have been specially designed for medium to strongly polluted cooling water, the focus of the development being on a high stability as well as on easy and economical installation. Therefore these fills are built from mechanically joint grids and are easily cleaned. The cooling tower fill packings are high-performance fills which provide an optimized pressure drop. We offer a unique flexibility in measures for this fill type.

2021/03/26

READ MORE

Get the latest price? We'll respond as soon as possible(within 12 hours)